"Research"

There’s only one way to start designing skis….

Some Reading and some math until finally...

I decided on a shape

I played around with the length, thickness profile, side-curve, material, width until I had what I thought would be a good ski for me. Then, I laser cut the profile to transfer onto the various materials I’d put in the ski

Now on to building them!

The core is the most interesting part of the ski. It gives it it’s characteristic springiness and particular stiffness, and naturally it’s also the hardest part to make. I made mine out of solid pieces of poplar — Most ski manufactures glue together a set of stringers and profile it from there.

Core Ready for profiling

My Home-made profiling jig. The rails on the side are cut to the shape of the ski. As I slide my router across the top, the profile appears!

Next step....Layup!

Bottom mold for shaping the finished ski. You can see the top mold in the background. Once everything was laid out and lathered with epoxy, I pressed the two sides of the mold together with some ratchet straps and…

Blank ski! Ready for finishing

First ski, complete with my janky paint job

After making my first ski, I figured I'd go and look into how the pro's do it

Just my luck! Parlor ski’s in East Boston has a ski building class. I got to make a (now actually functional) set of skis which I ride to this day.

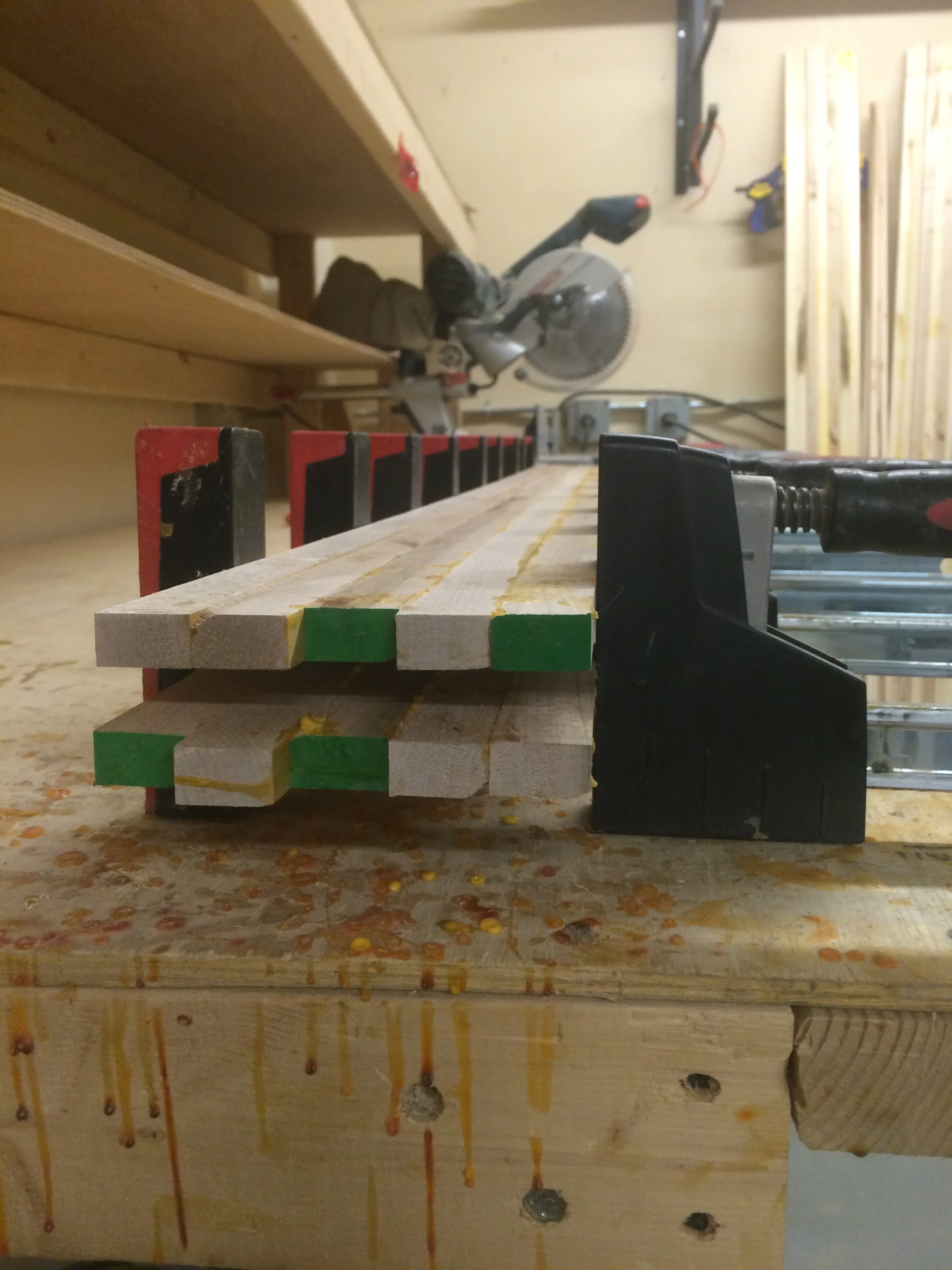

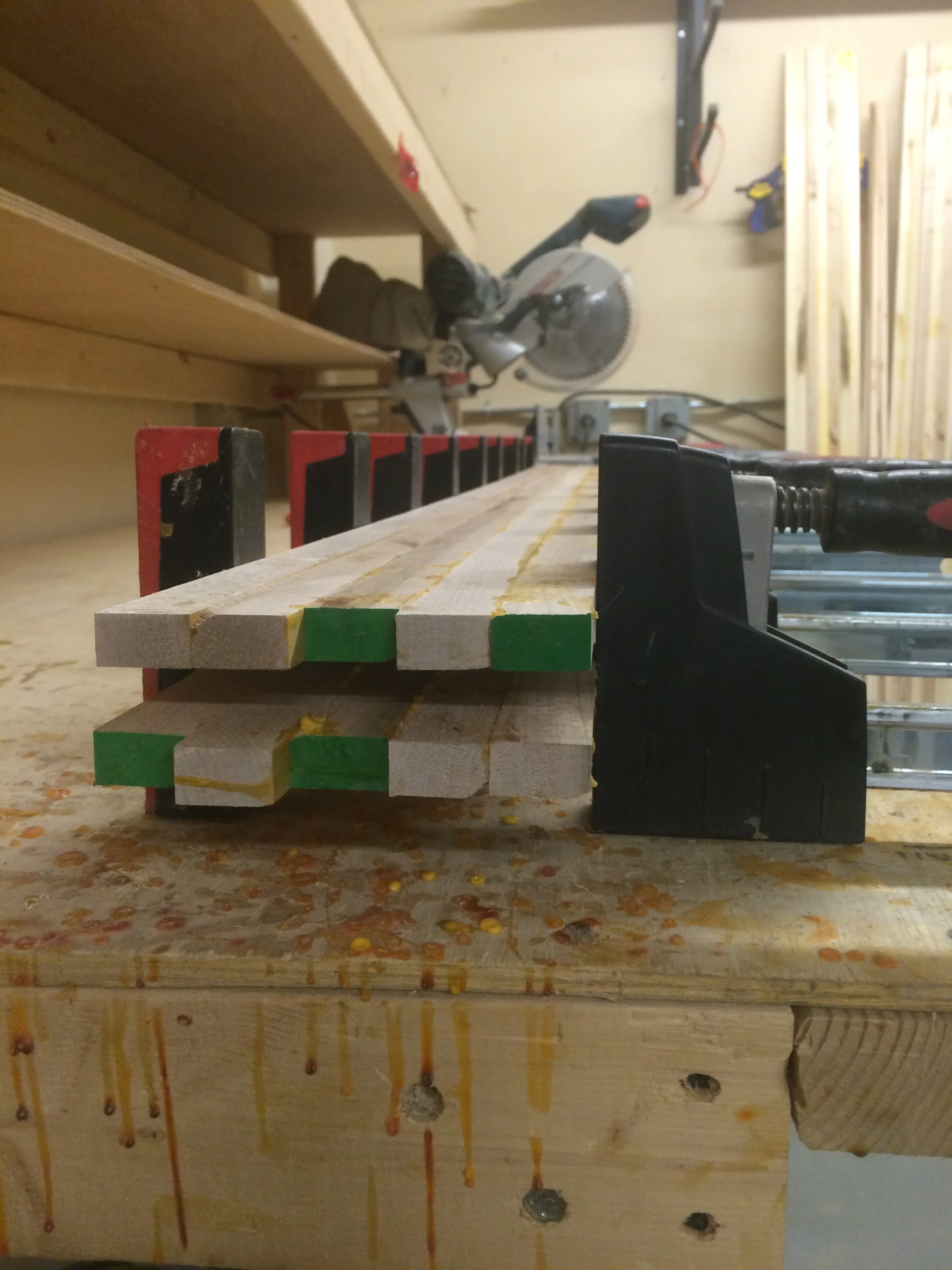

Gluing down the edges

Gluing the core from maple stringers

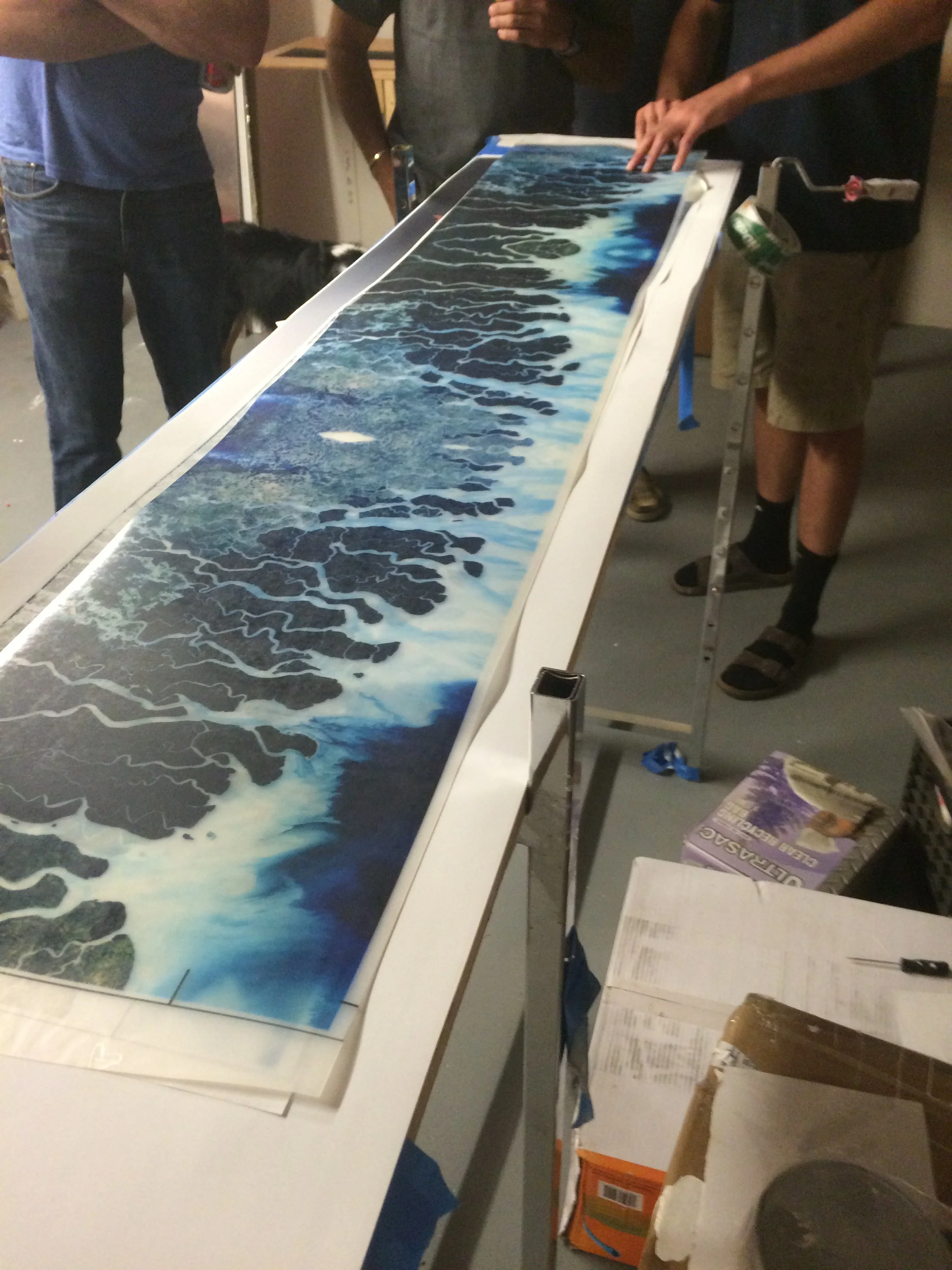

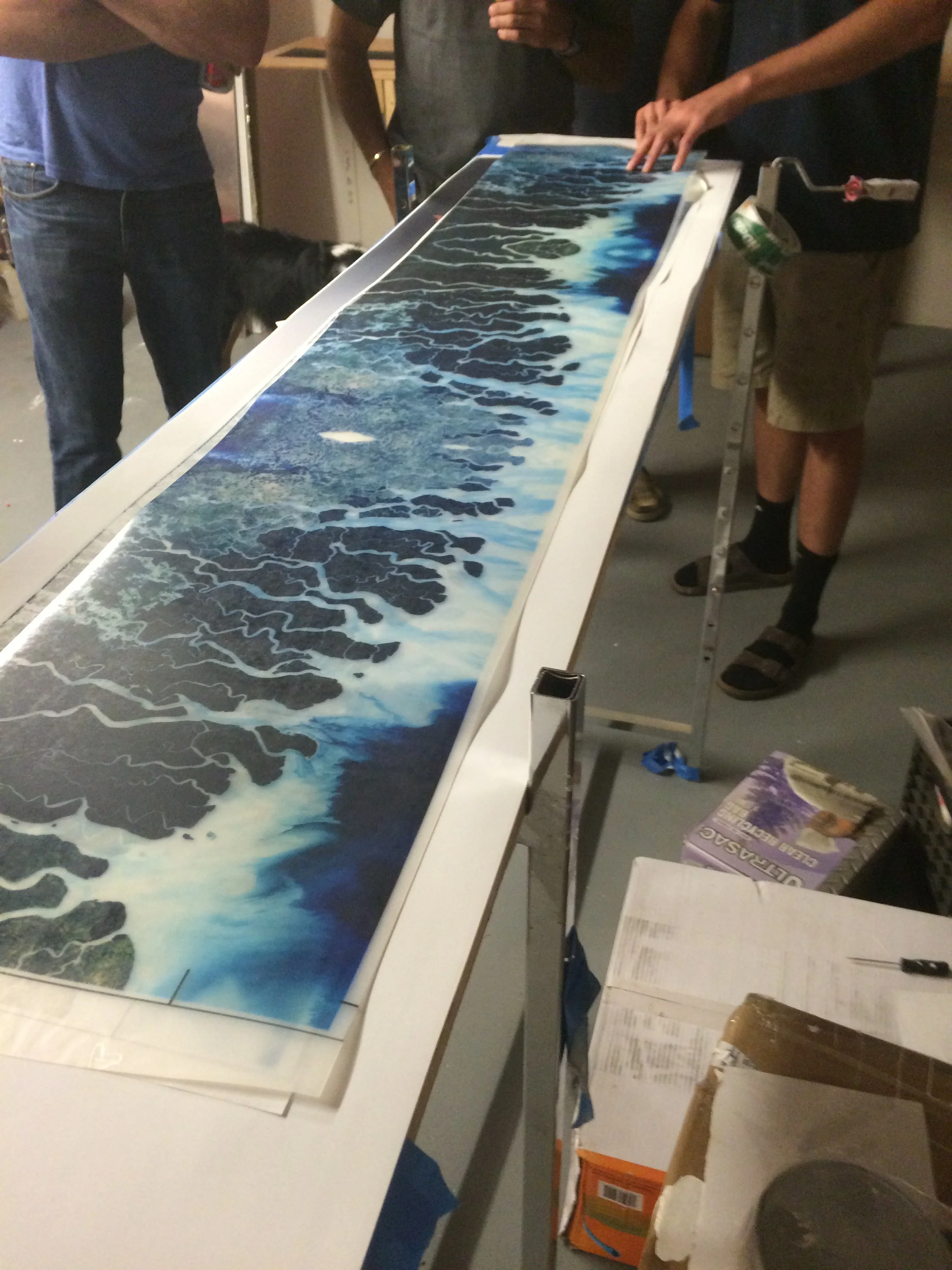

Topsheet Design