rise

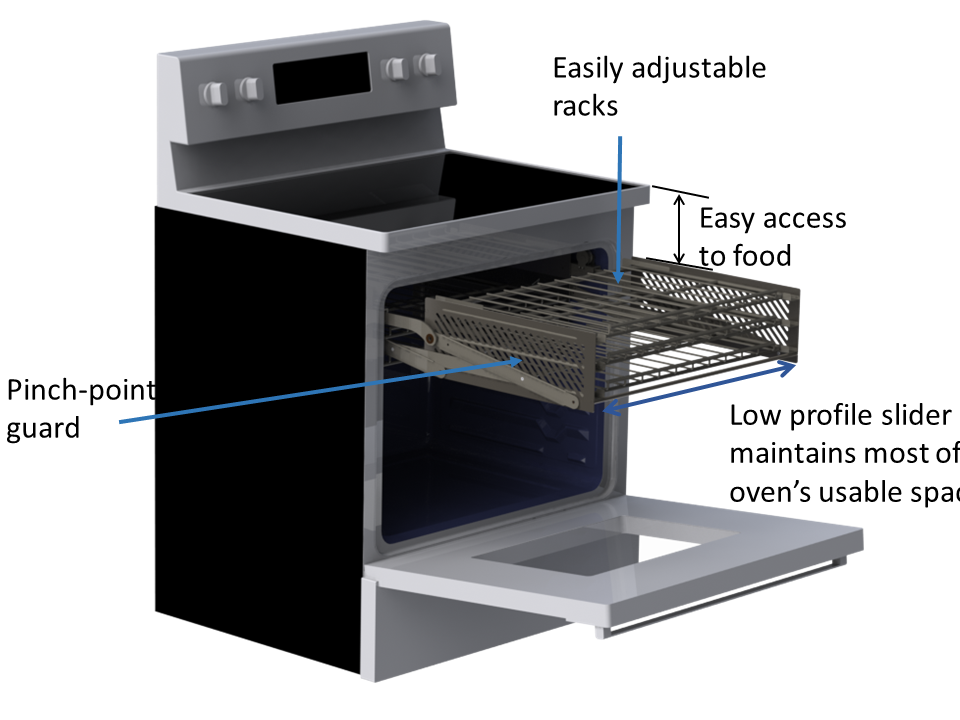

After a half-semester of researching and developing a product concept which we could take to the alpha-prototype stage, we settled on rise, the easy access oven rack.

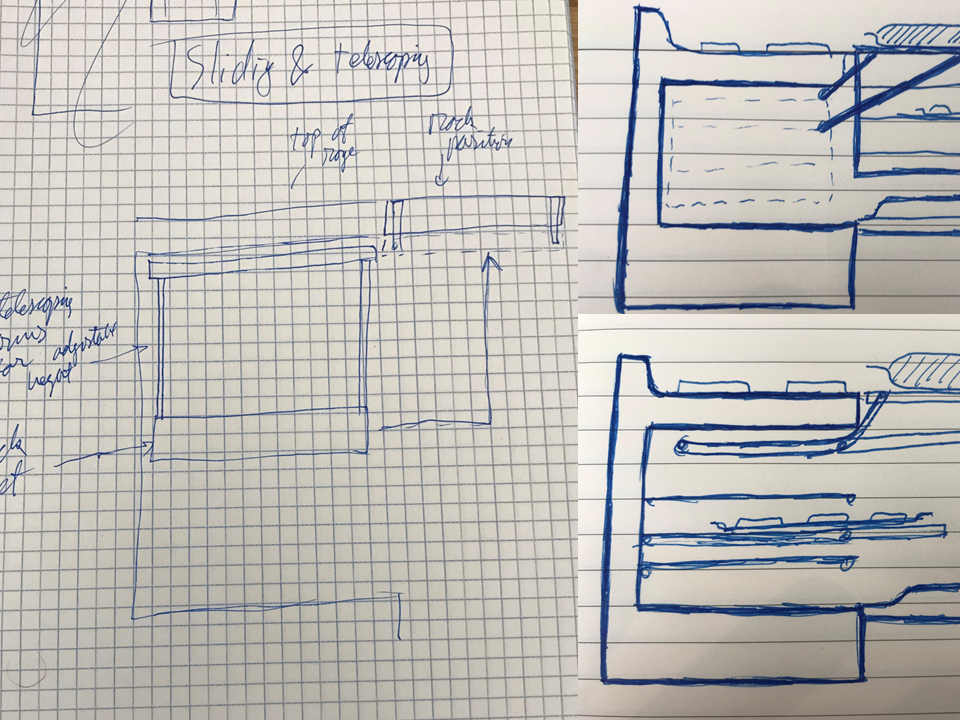

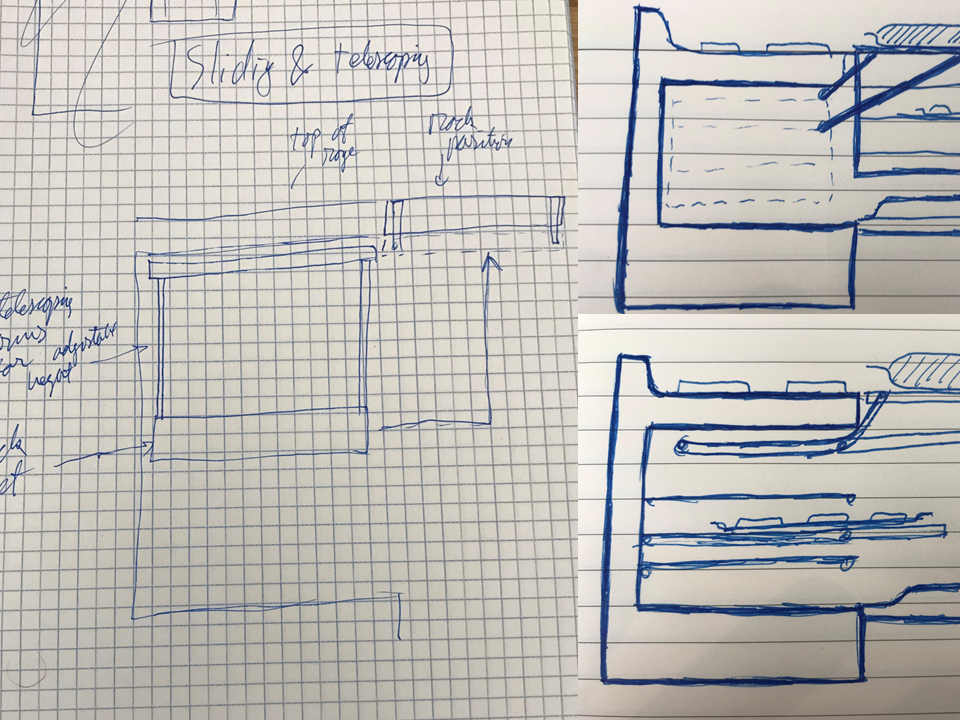

Sketching and concept development

Each person on our team was tasked with creating a variety of sketched design concepts to stimulate discussion for how we should move forward on the project.

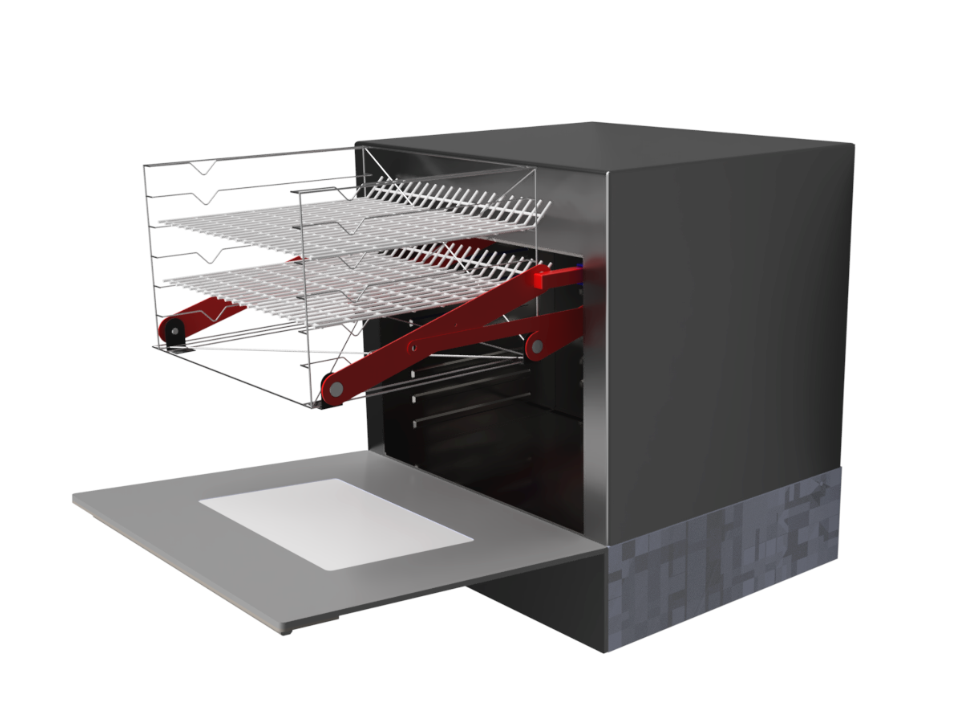

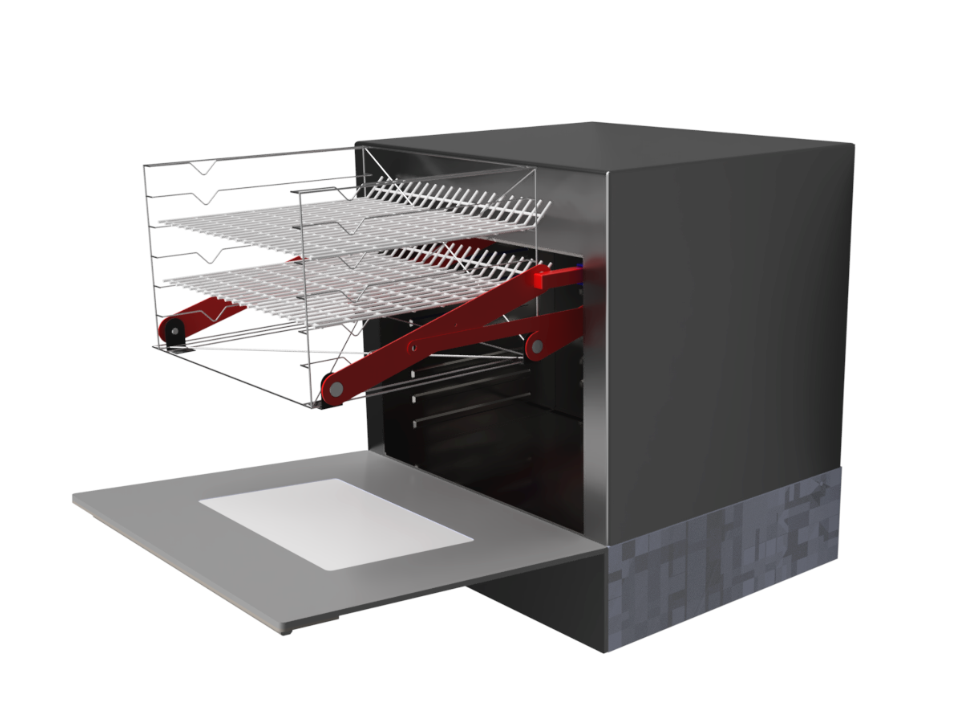

Initial prototype CAD model

A simple CAD model to demonstrate the physical architecture and integrated design for our first prototype.

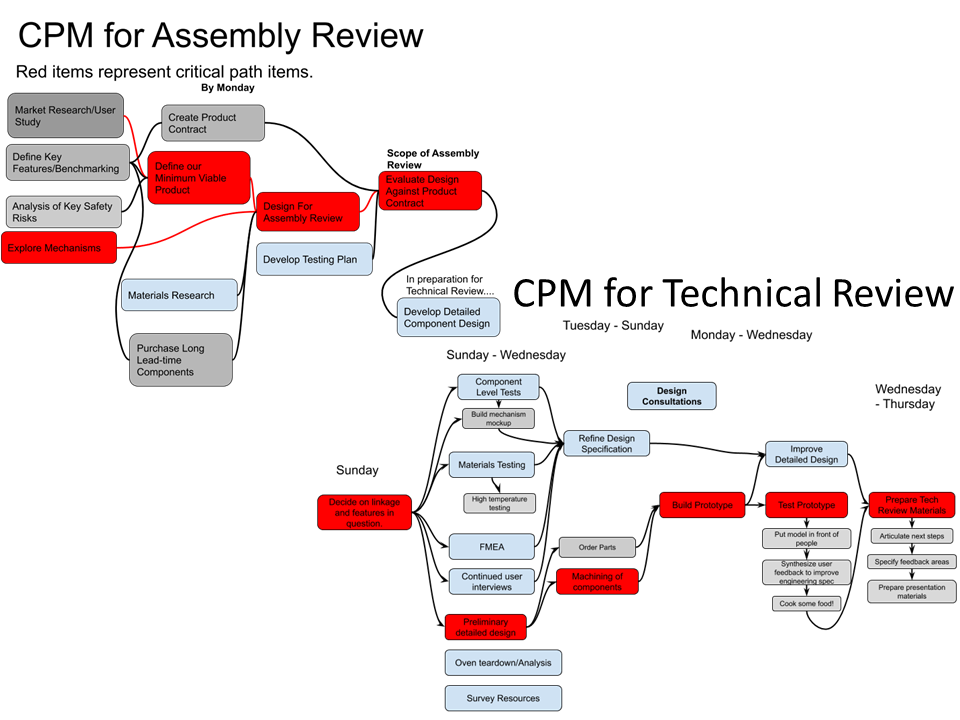

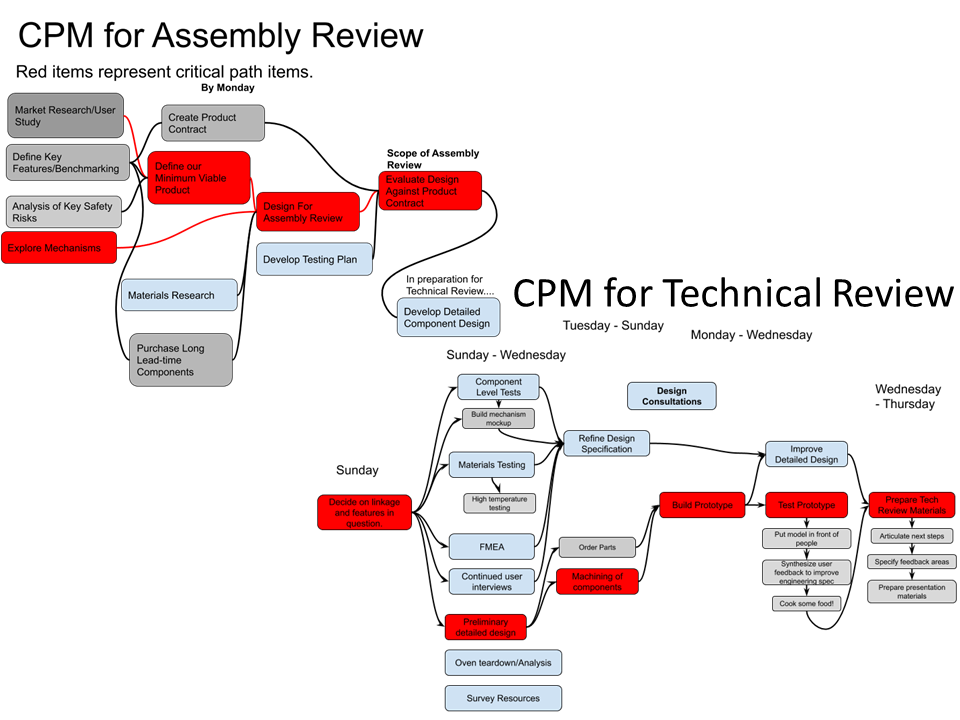

Critical Paths

As part of my role on the team, I was tasked with ensuring that we had a solid schedule for the development of the prototype. I used a CPM to work out for myself and demonstrate to my teammates where we were in the project and delegate effectively.

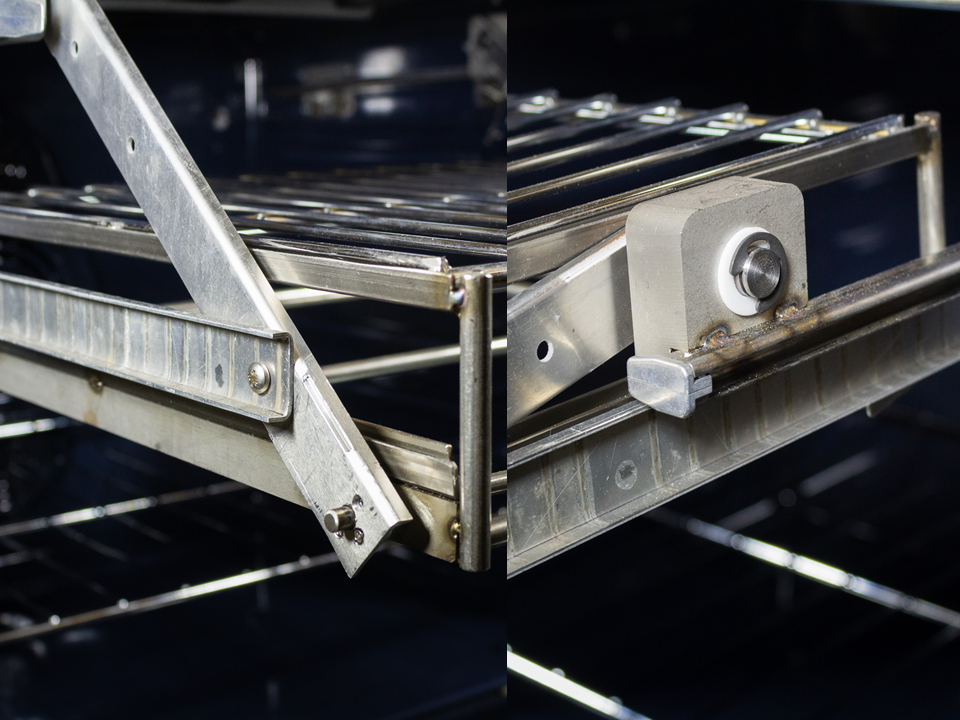

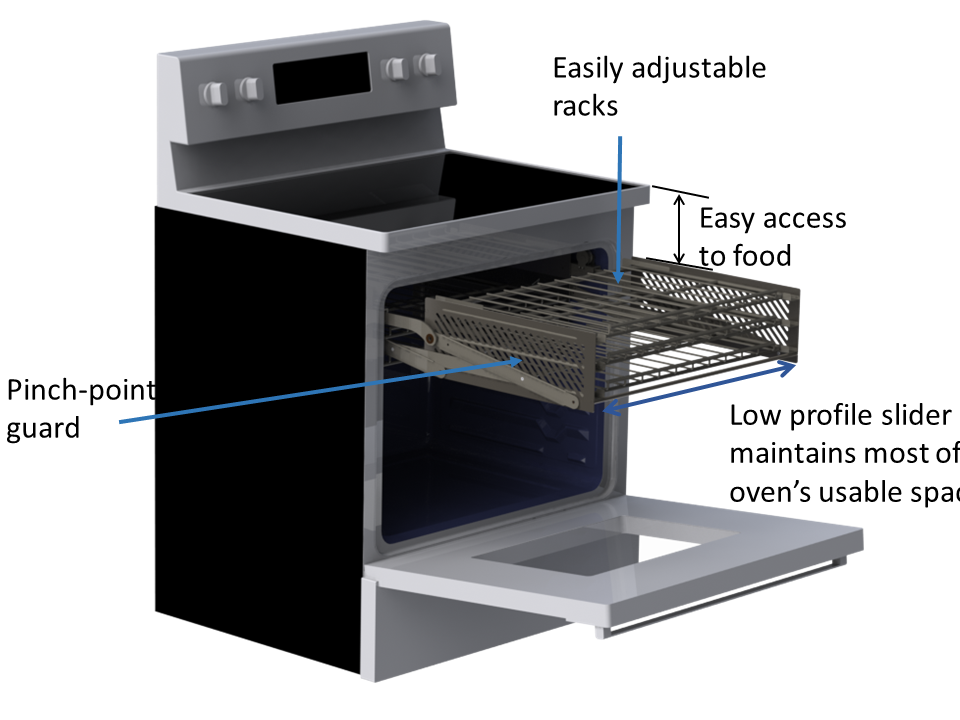

First Prototype

We built our first prototype by retrofitting off the shelf oven sliders with a swinging platform. The mechanism was actuated by two windshield wiper motors.

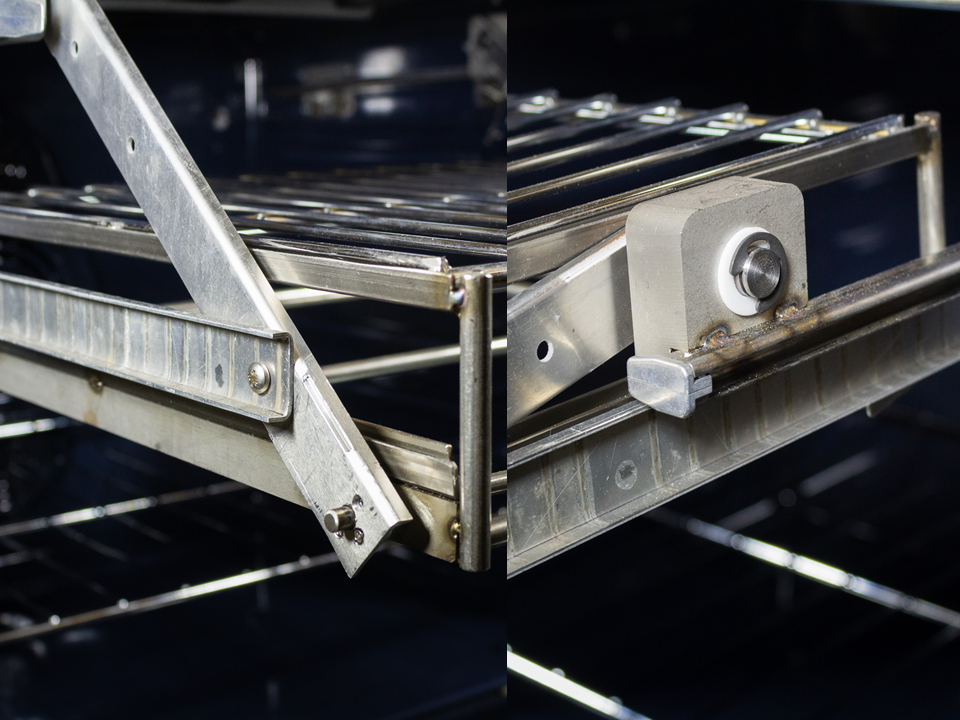

Details of first prototype

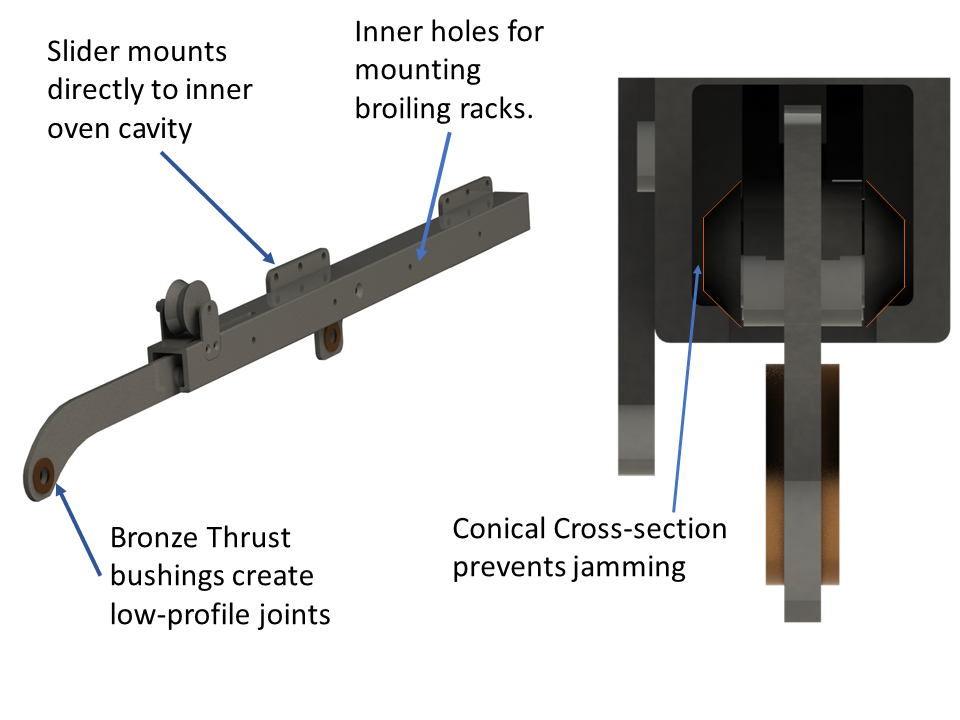

How to create effective rotating connections was a critical aspect of our initial prototype. In this iteration we used PTFE bushings, which we eventually found where too low friction and lead to swinging.

CAD model for alpha prototype

After conducting more user testing with our first full prototype, we refined our design to address some of the critical issues our users had identified.

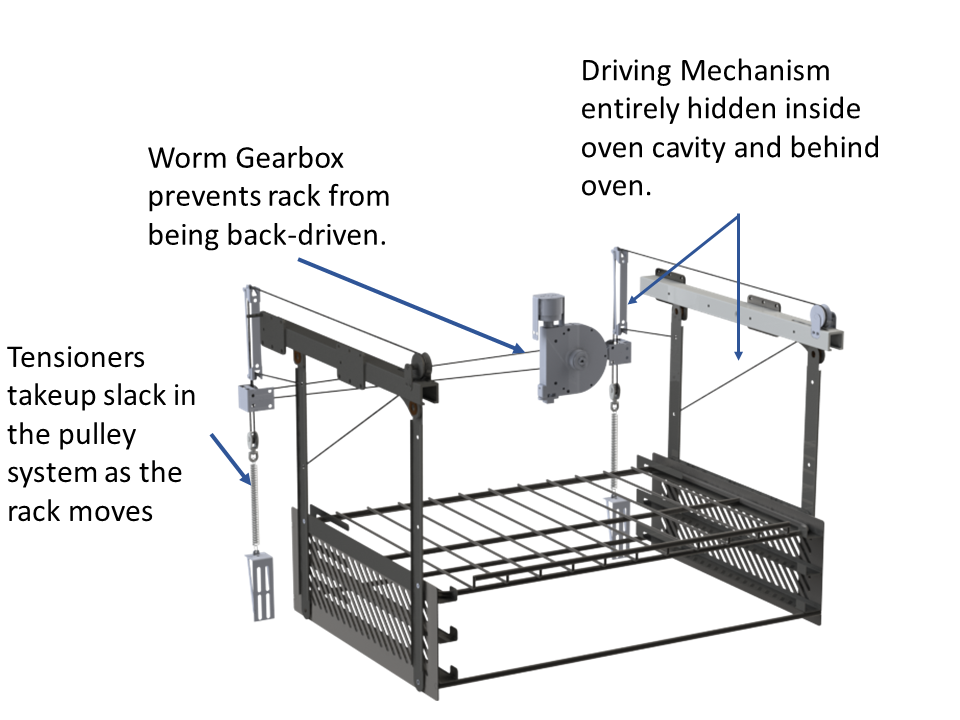

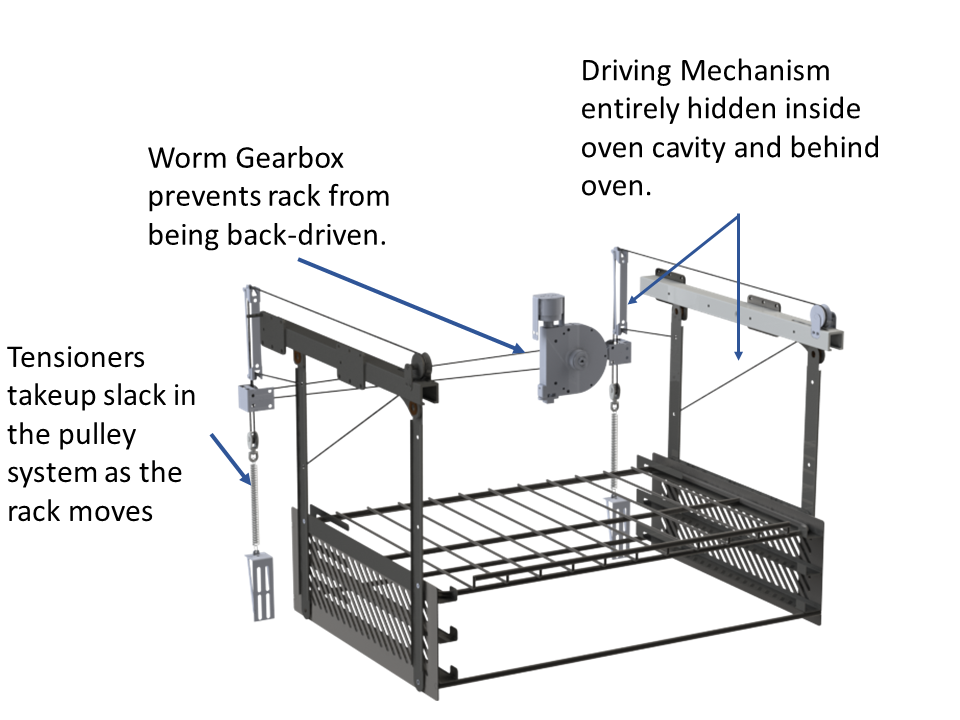

Behind The Scenes

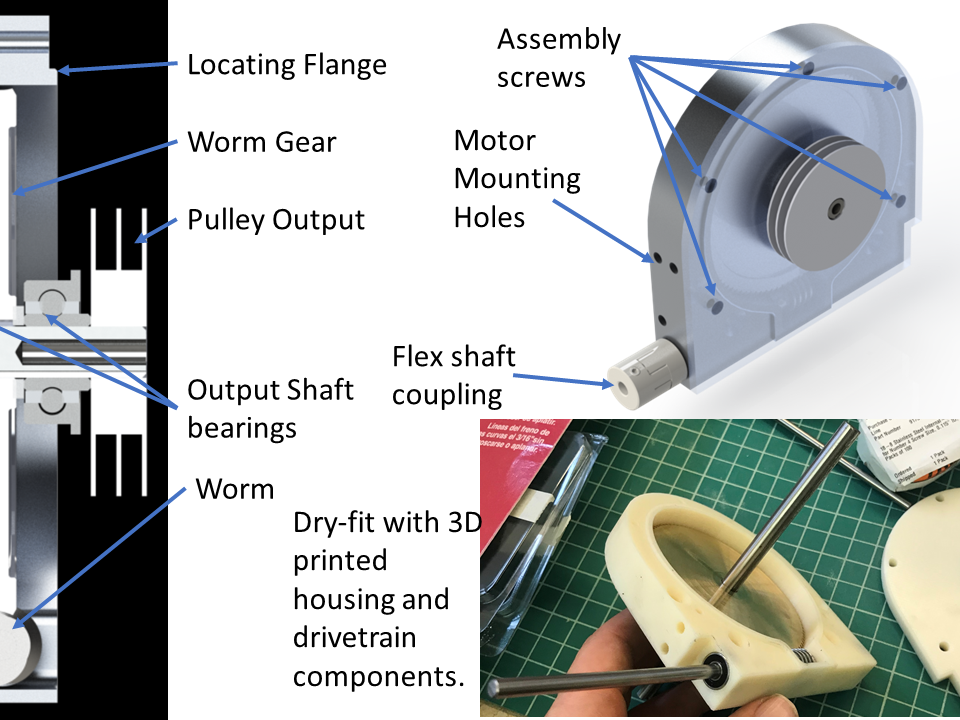

One major advantage of the driving mechanism we chose was that it could be completely concealed in the oven cavity and took up no more space in the oven than the sliders themselves. The gearbox drives the motion of the rack in two degrees of freedom, which creates the desired “up and out” motion that our users liked.

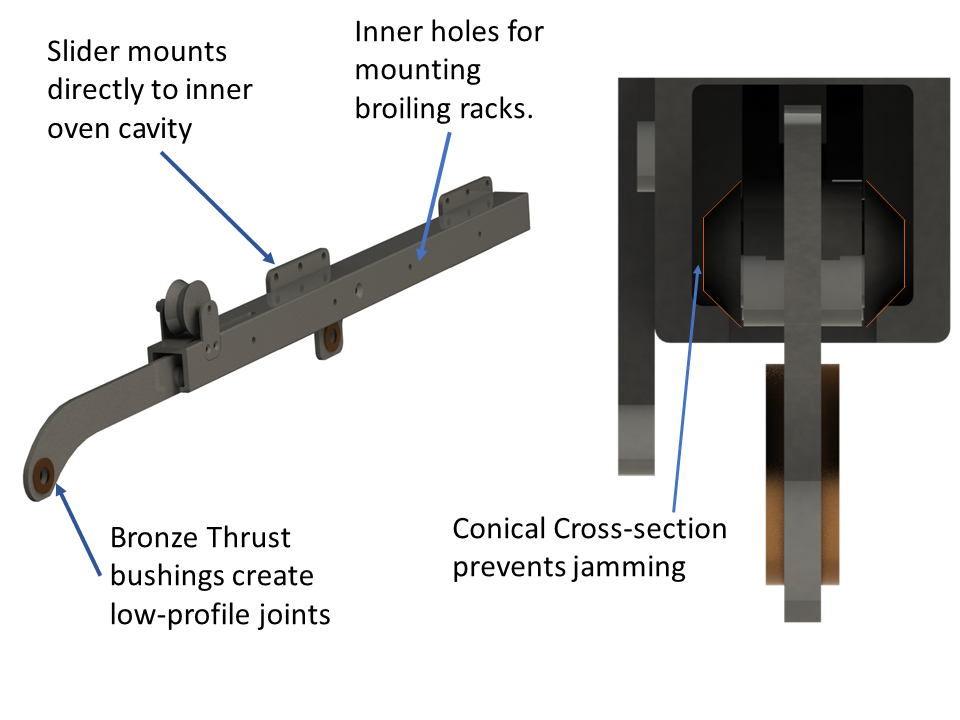

Slider Design

As part of the development of our alpha prototype, we decided to design our own sliders which took up less space inside the oven and allow us to optimize the trajectory of the oven rack according to our useability goals.

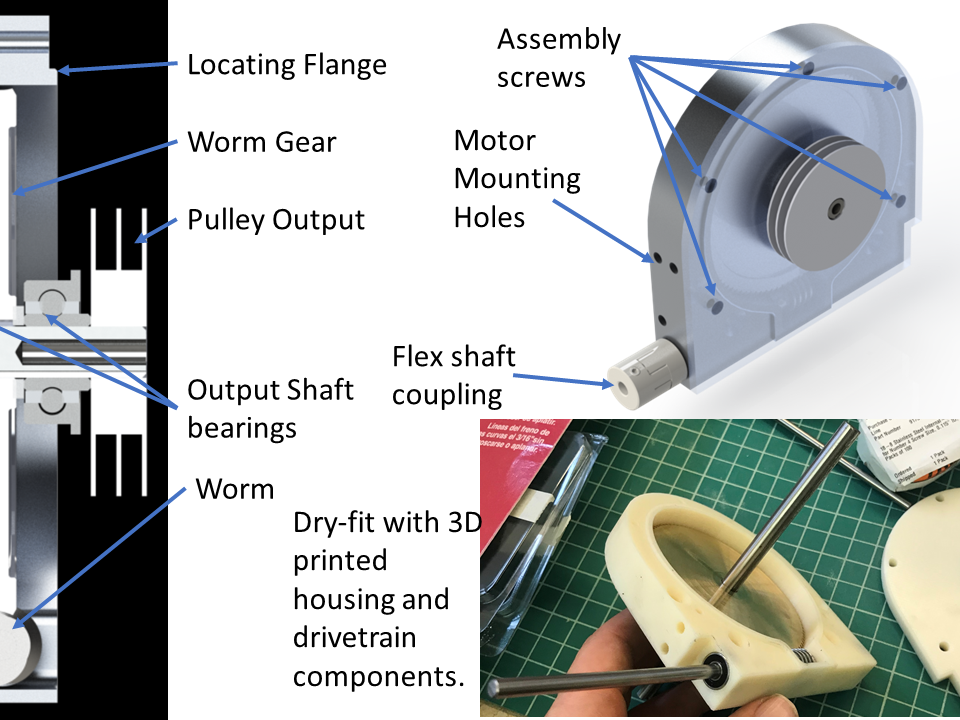

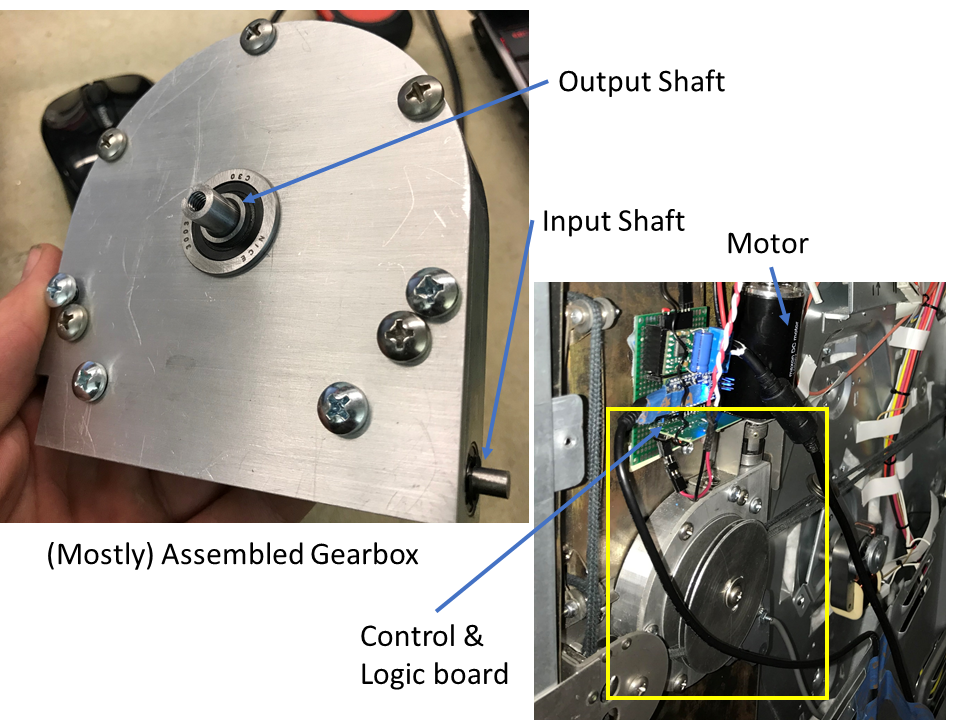

Gearbox

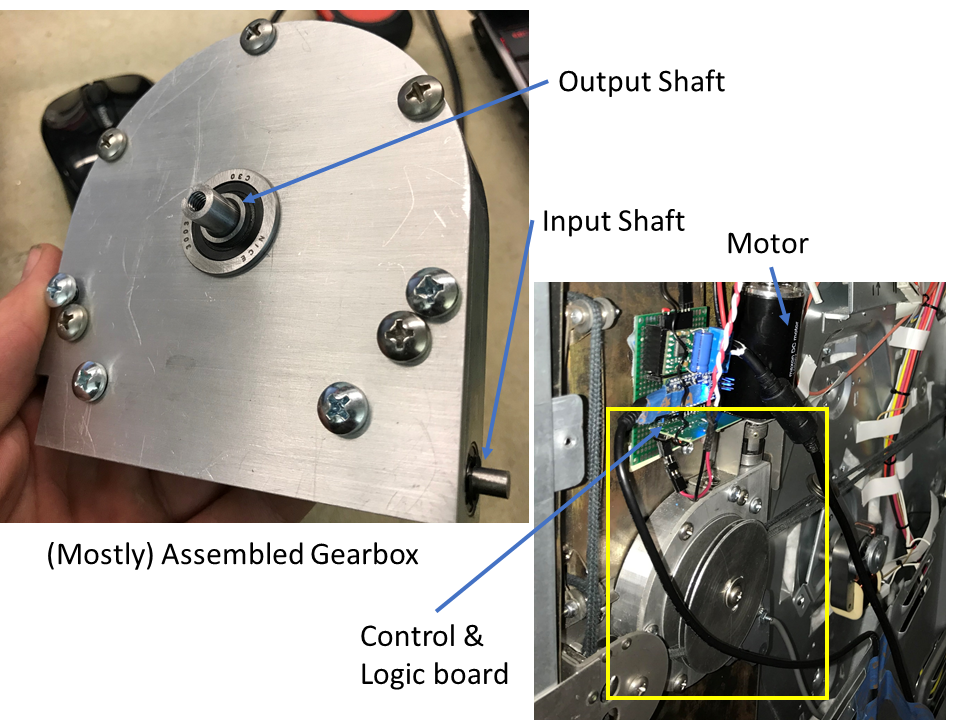

Driving the four-bar rack mechanism is a worm-gearbox. It provides a 100:1 reduction and prevents the rack from being back-driven. The output shaft is well supported by two large bearings, and the output forces on the shaft are configured such that very little net bending force is applied to it.

Gearbox Installation

Once we fabricated the gearbox, we mounted it behind the oven and routed the cables from inside the oven to the back of the oven.

Alpha Prototype

After a couple of sleepless nights, we had a completed alpha prototype for rise. As with any prototype, we had some issues with lifting the full load, but functional enough to demonstrate the desired features for the final presentation.

2.009 Gallery and other links