Covid-19 Lockdown Project

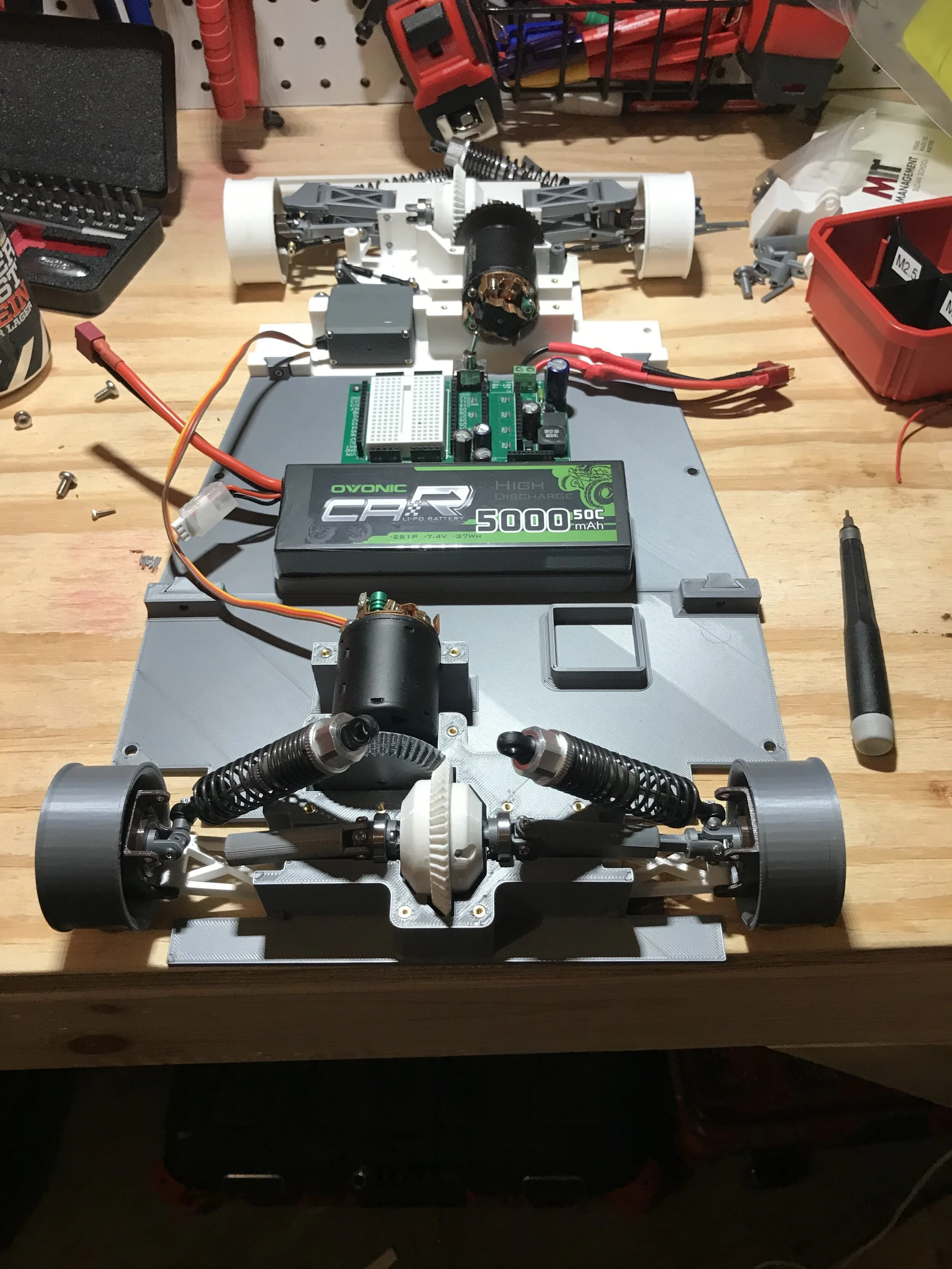

Partially to maintain sanity, partially to hone in my 3D printing and Mechanical design skills, mostly because cars are cool and this was fun, I am excited to share my (mostly) 3D printed remote control car. This is still a work in progress, slowly building up complexity through a number of design iterations. The goal is to design a remote control car from the ground up with AWD, full suspension, and enough power to make it wicked fun to drive around. I’ll probably share my design on Thingiverse when all is said and done, but for now the development continues!

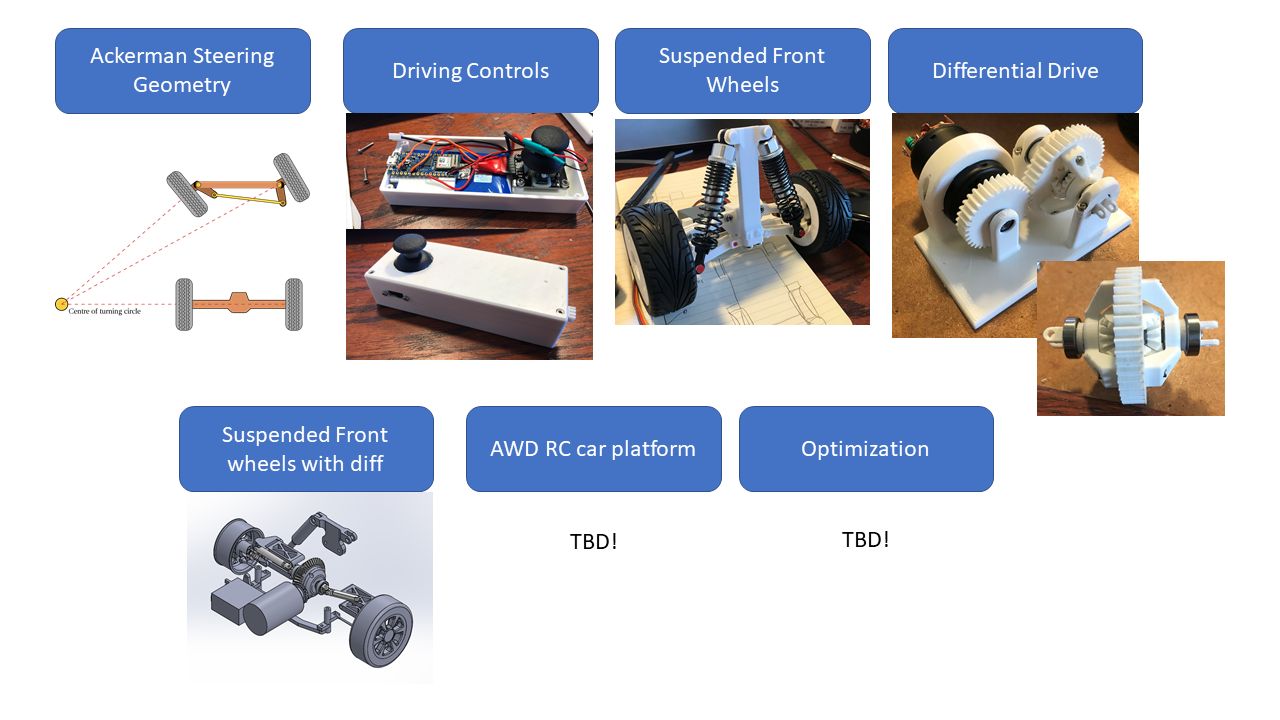

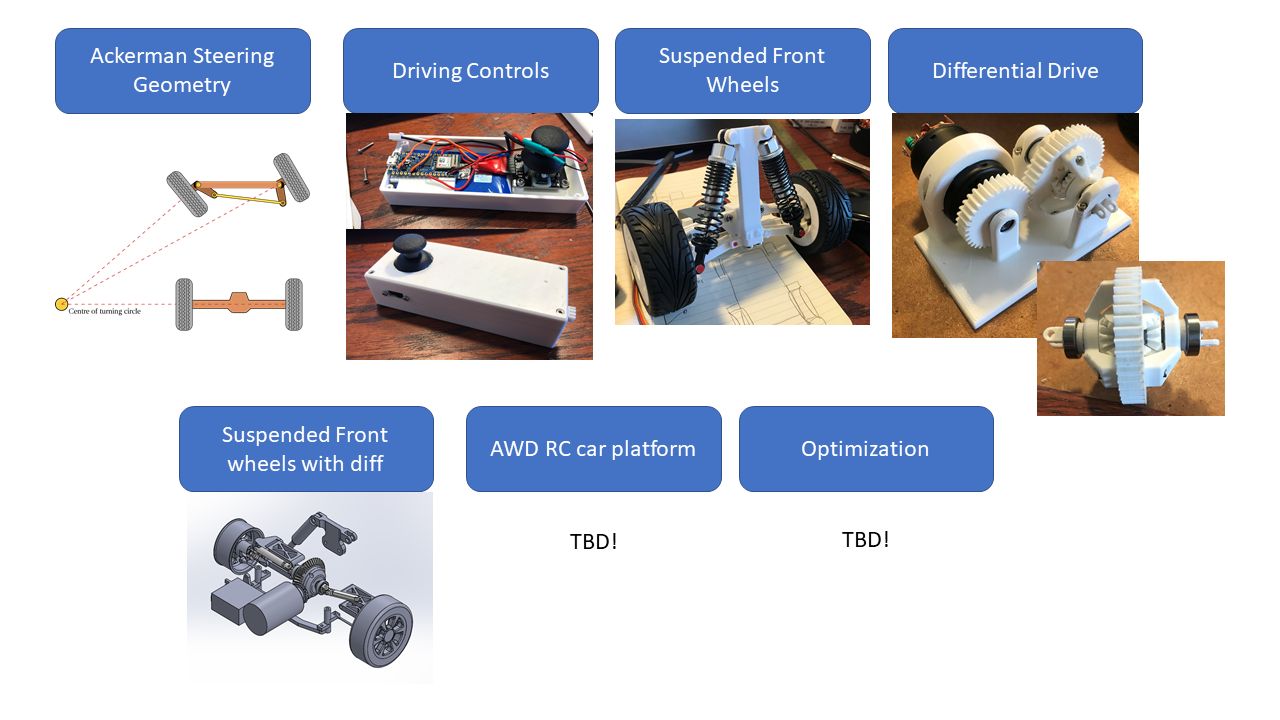

Planning the prototypes:

Step 1: Prototype Ackerman Steering Geometry.

Step 2: Prototype remote control, electronics and BLE connection between remote and the car.

Step 3: Add suspension to front wheels, while maintaining Ackerman Geometry

Step 4: Prototype Differential gearbox as the first step towards AWD

Step 5: Add a motor to the front wheel assembly, while maintaining the steering and suspension.

Step 6: Add suspension to back wheels, integrate back and front wheels into a single design.

Step 7: Optmize, make the car better faster stronger!

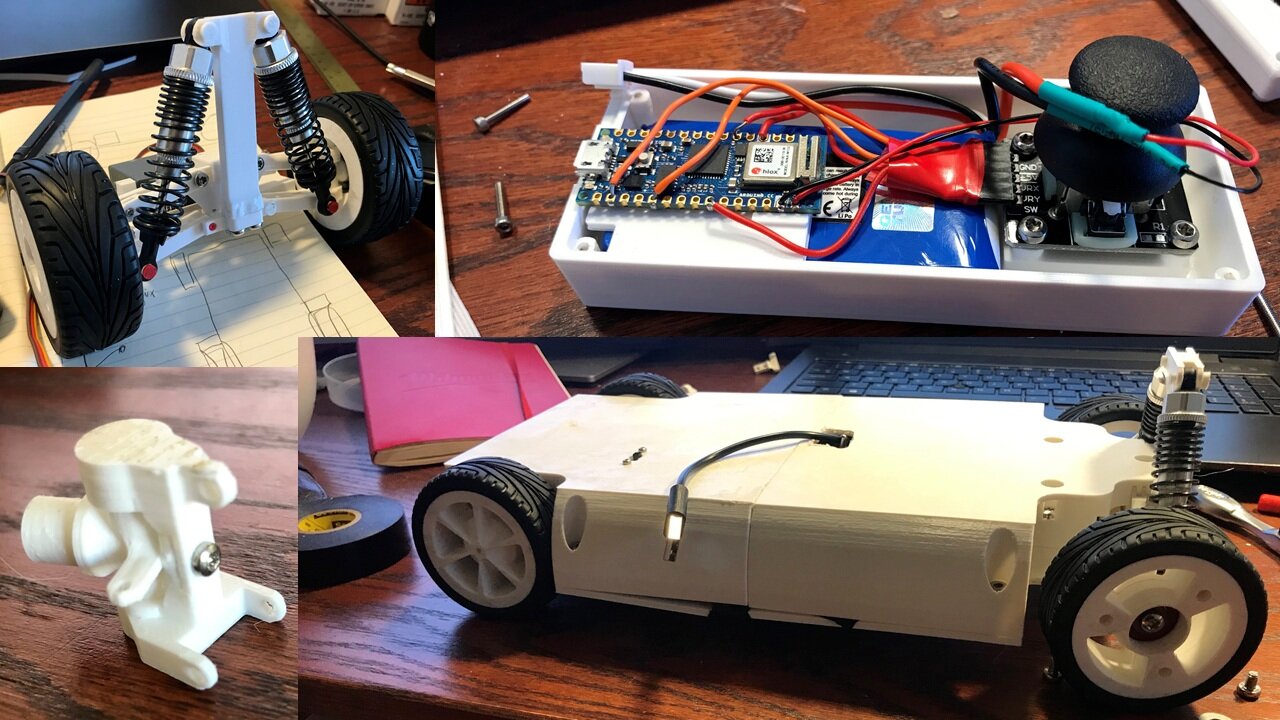

Rev 1

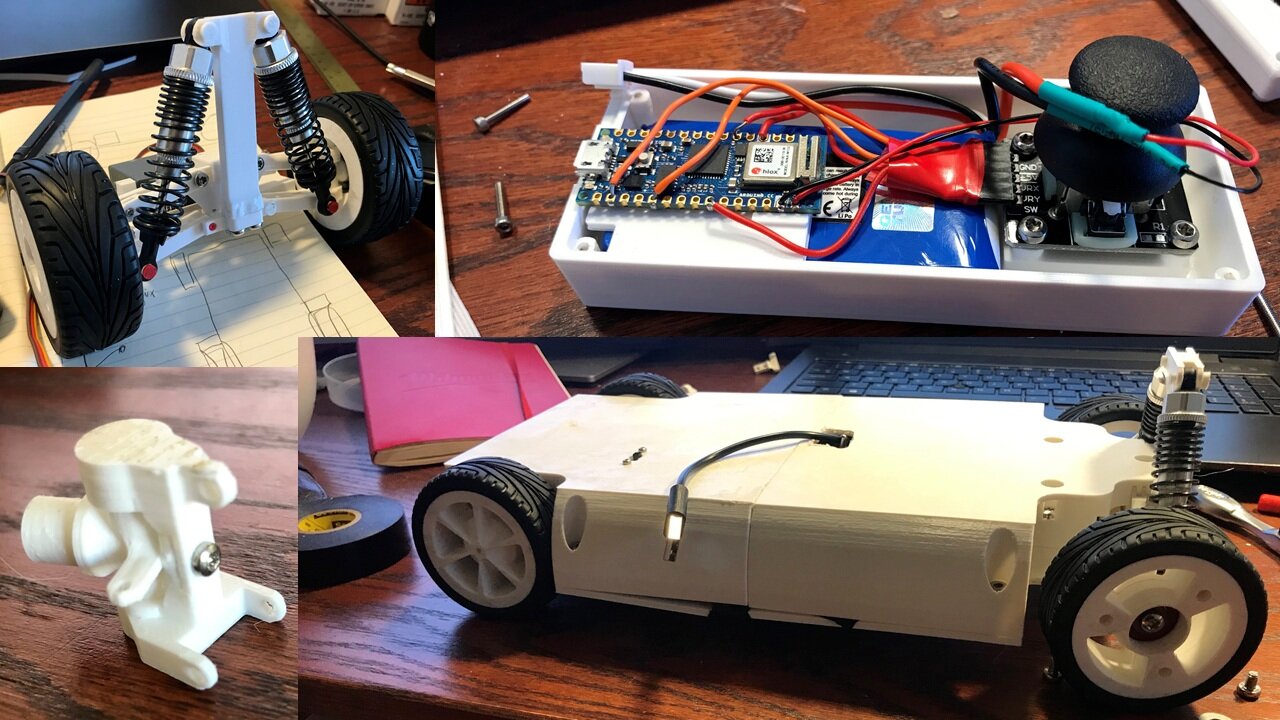

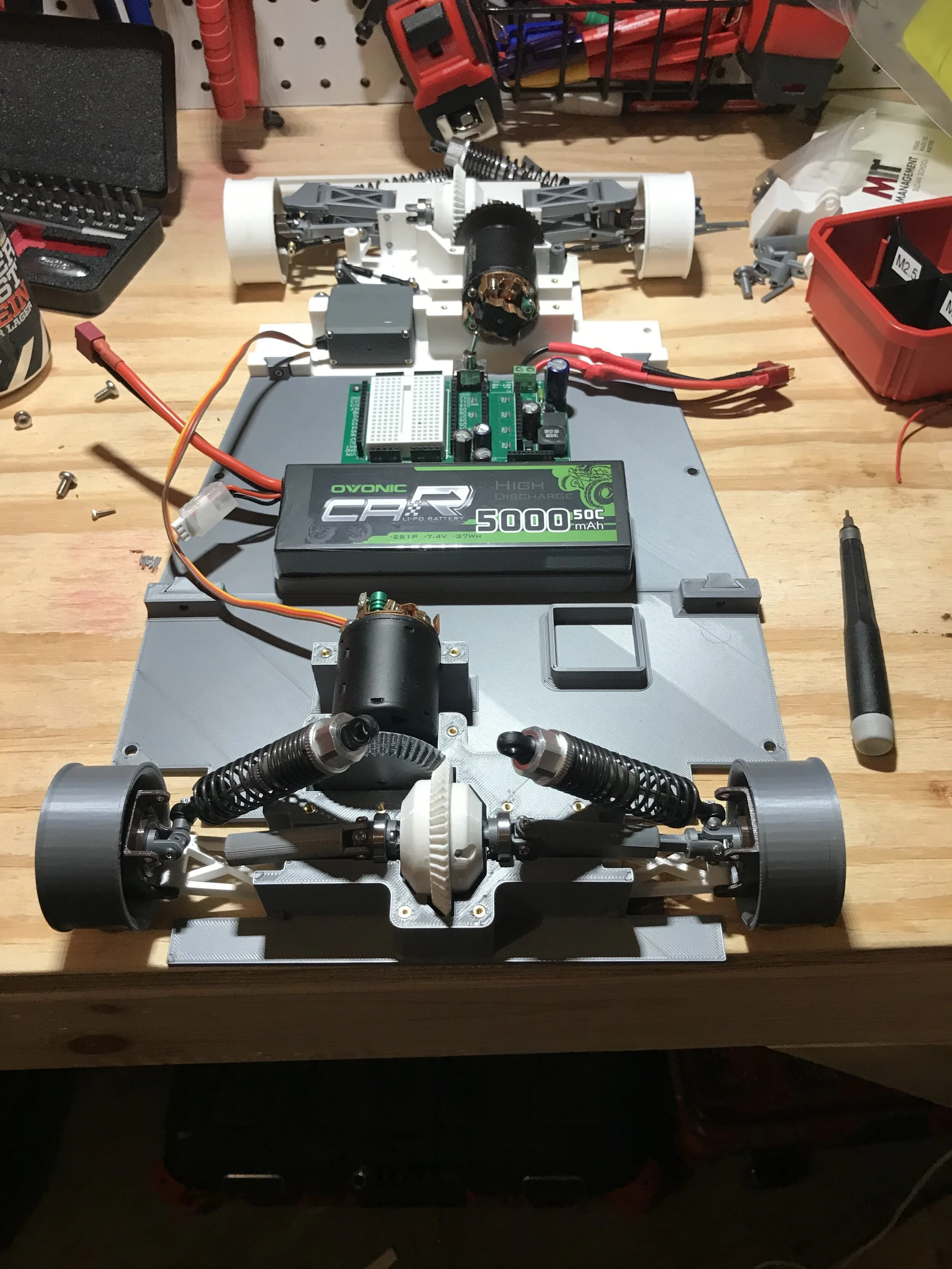

My first prototype as a very simple car with no suspension and only rear-wheel drive. Used this prototype to develop the controls and electronics for the car, as well as understand the limitations of the PLA I’m using to make these quick prototypes.

Rev 2

Large design overhaul in a lot of aspects. I spent some time working on understanding the capabilities of the car given the motors I’m using and found that it would be beneficial to the stability and acceleration of the car if I increased the overall footprint. This also allowed me to take some very small plastic parts and make them more rigid and durable, as I tested the limits of what the PLA could handle. I also experimented with a sort of clam-shell design to improve assembly time and the overall rigidity of the car.

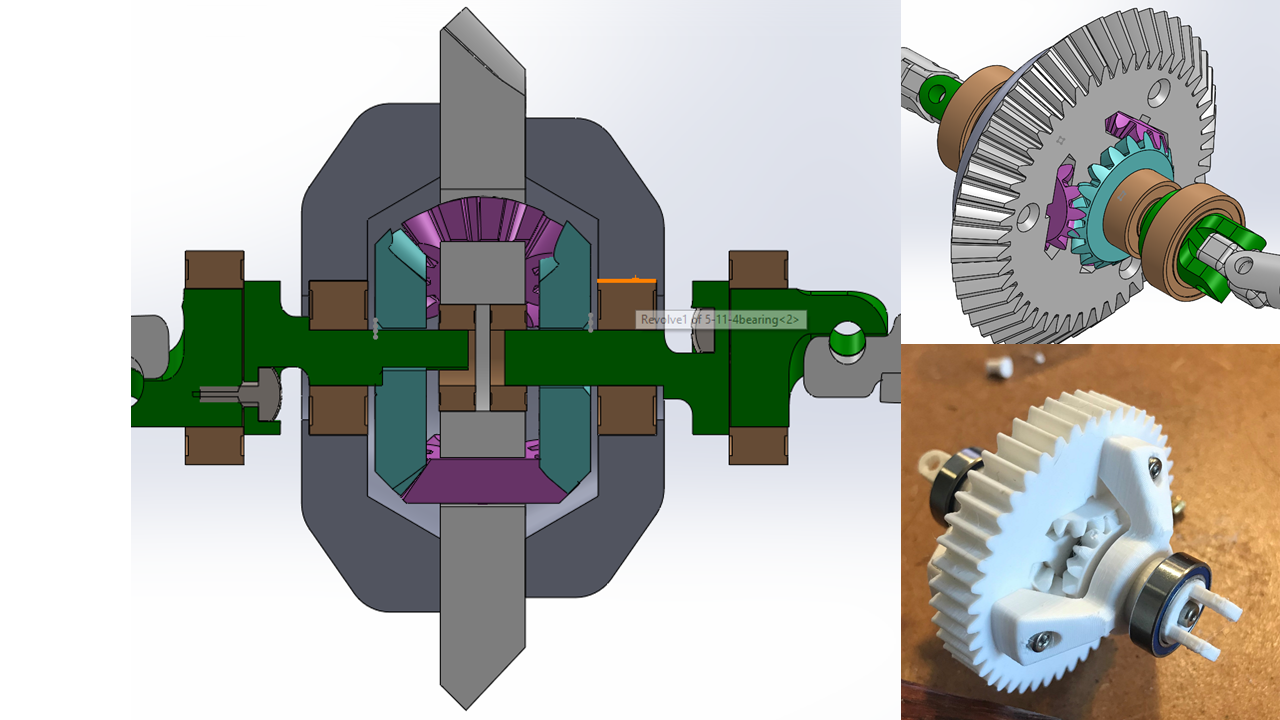

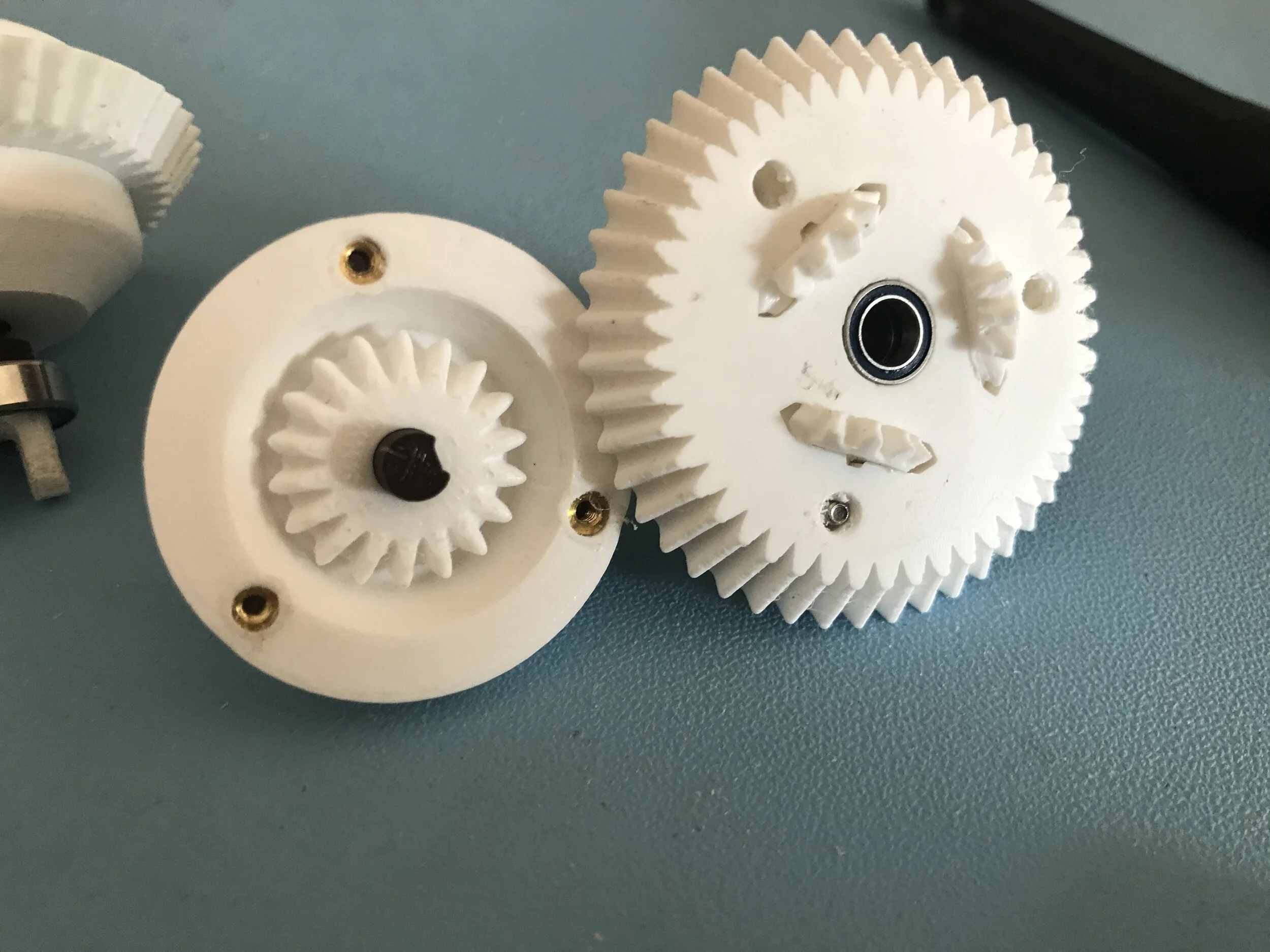

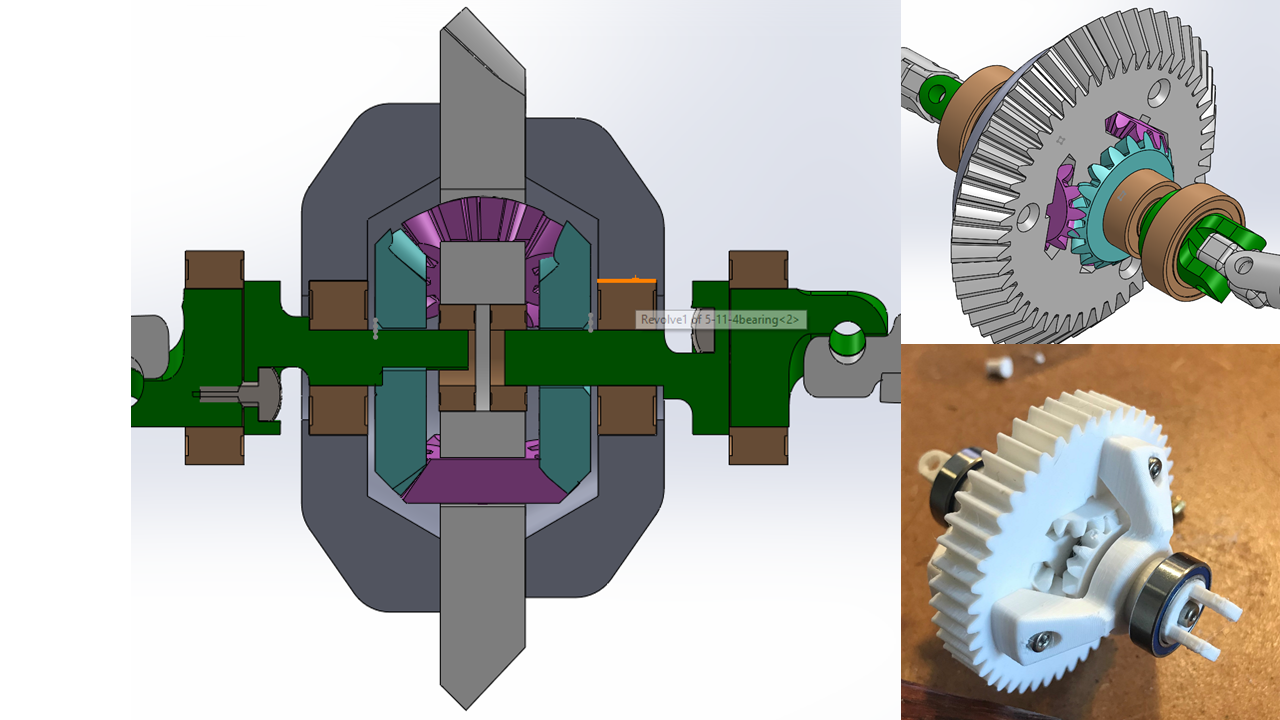

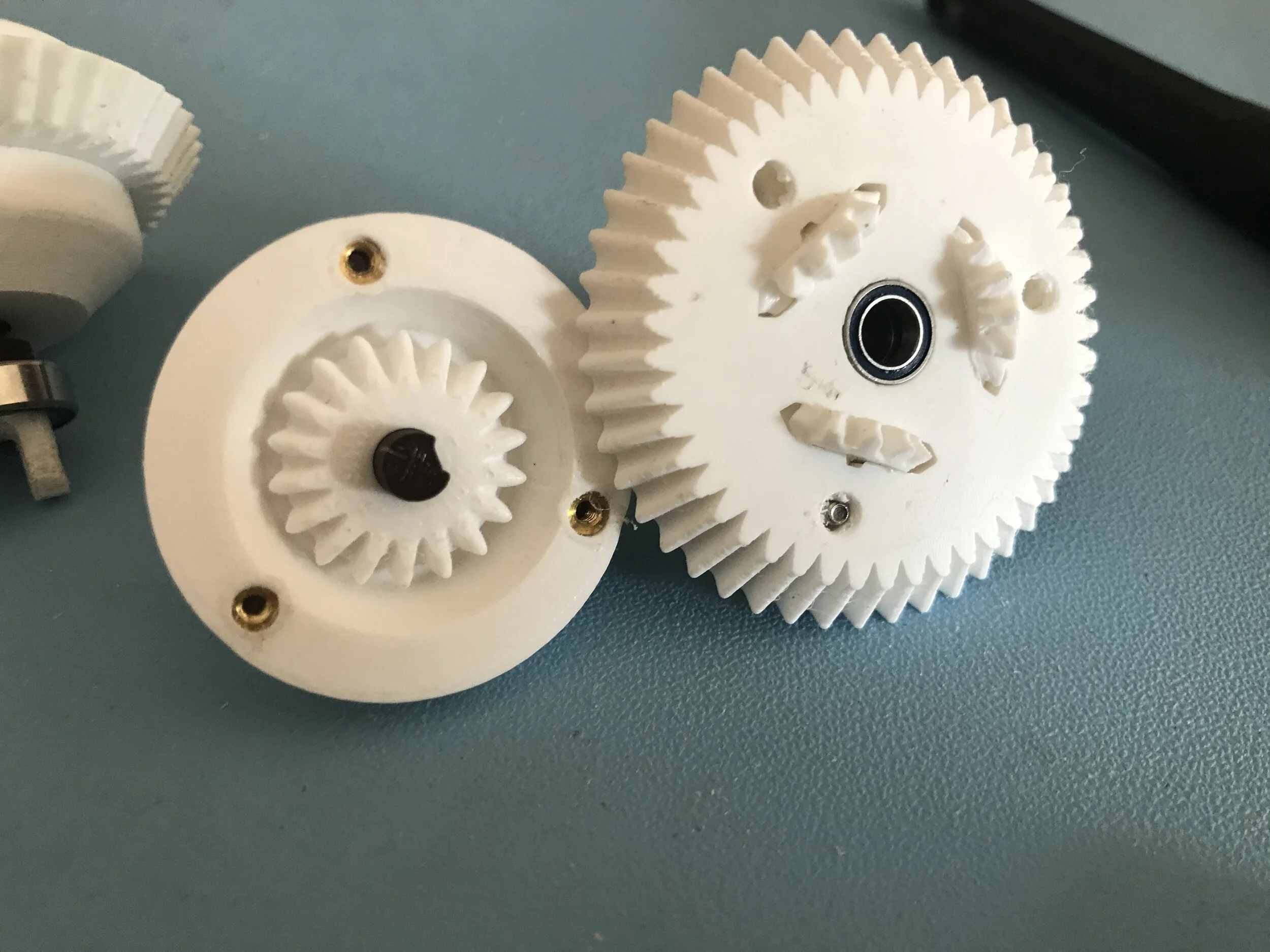

Differential

Two revs of differential gearbox prototypes. Added the Miter gear to the outside to keep the motor from shifting the CG and moments of inertia of the car too far from the centerline. The miter gear also helped add the flexibility I needed to fit the steering, powertrain, and suspension components into the front wheel assembly.

Rev 2 for differential gearbox.

The size of the gearbox is driven by the resolution of the 3D printer. A modulus of 1 (metric) is the smallest pitch I managed to print.

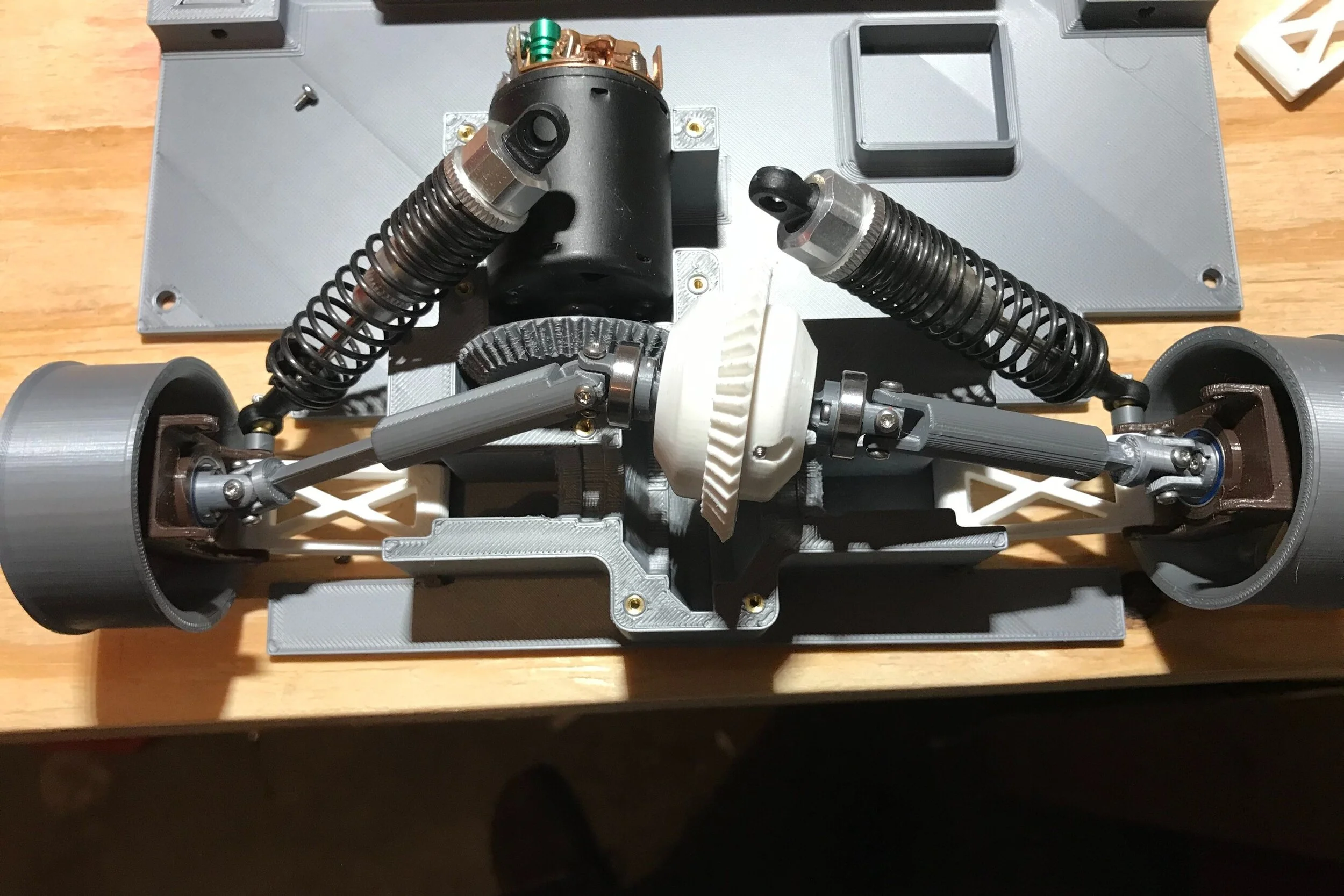

Four Wheel Drive front-end

The biggest challenge with making a four-wheel-drive car is to fit a differential, motor, and steering linkage into the front end. The next biggest challenge is fighting that space constraint while maintaining the strength and stiffness of the transmission.

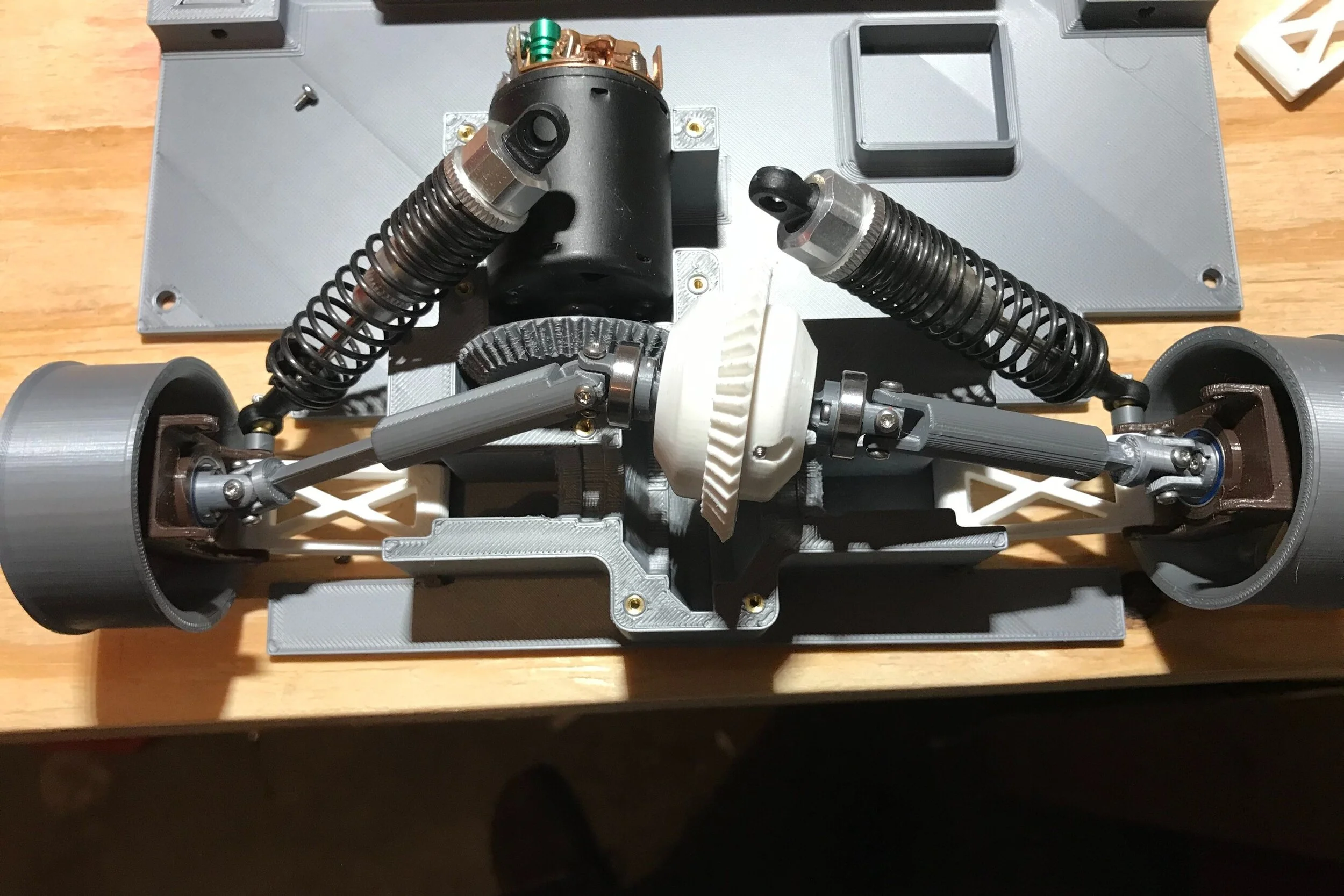

Back end of the fully-suspended car

I tried to reuse as many components for the back end as the front end, as these wheels don’t need to rotate like the front wheels do to steer, so it’s a much simpler overall mechanism.

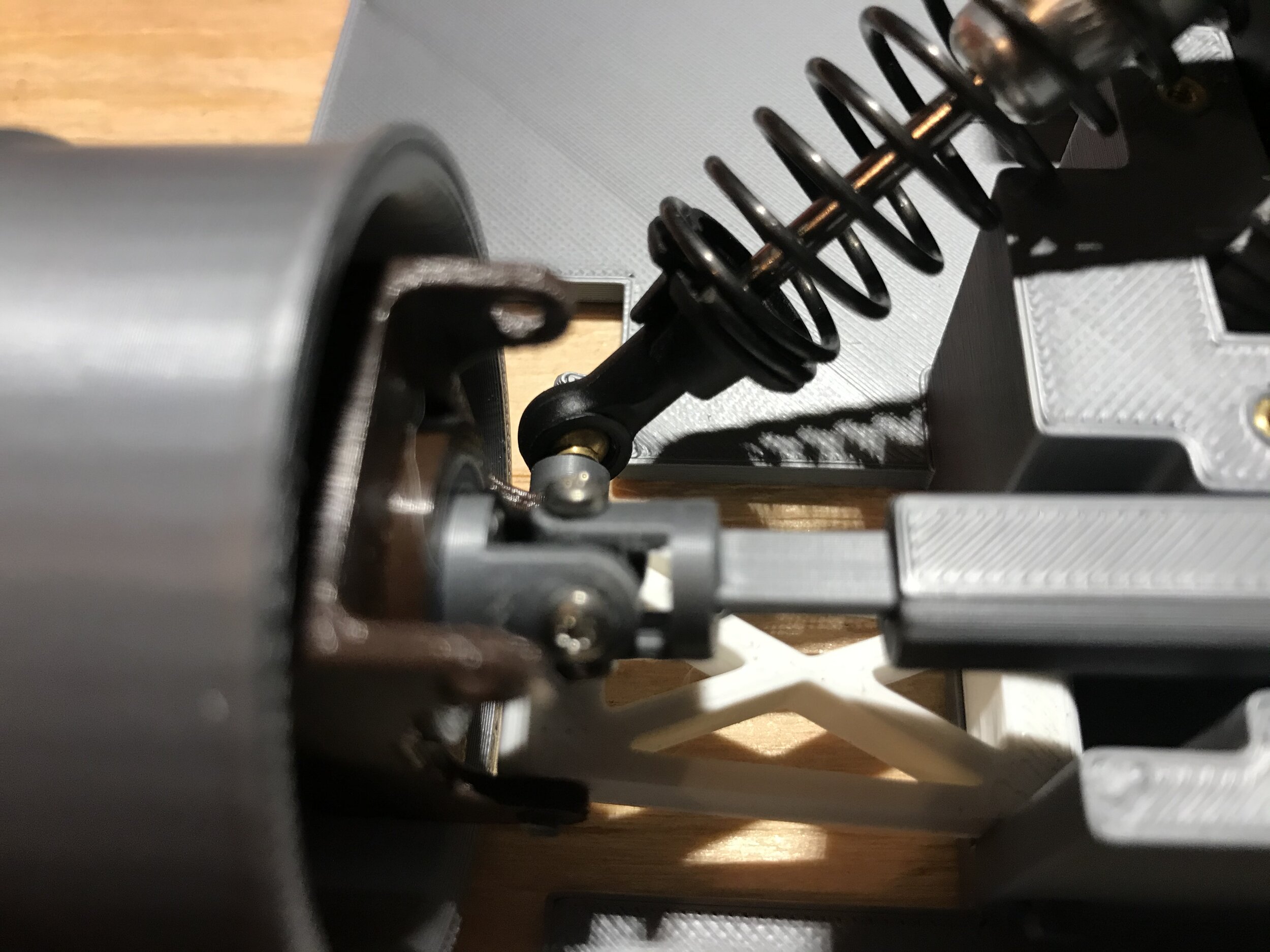

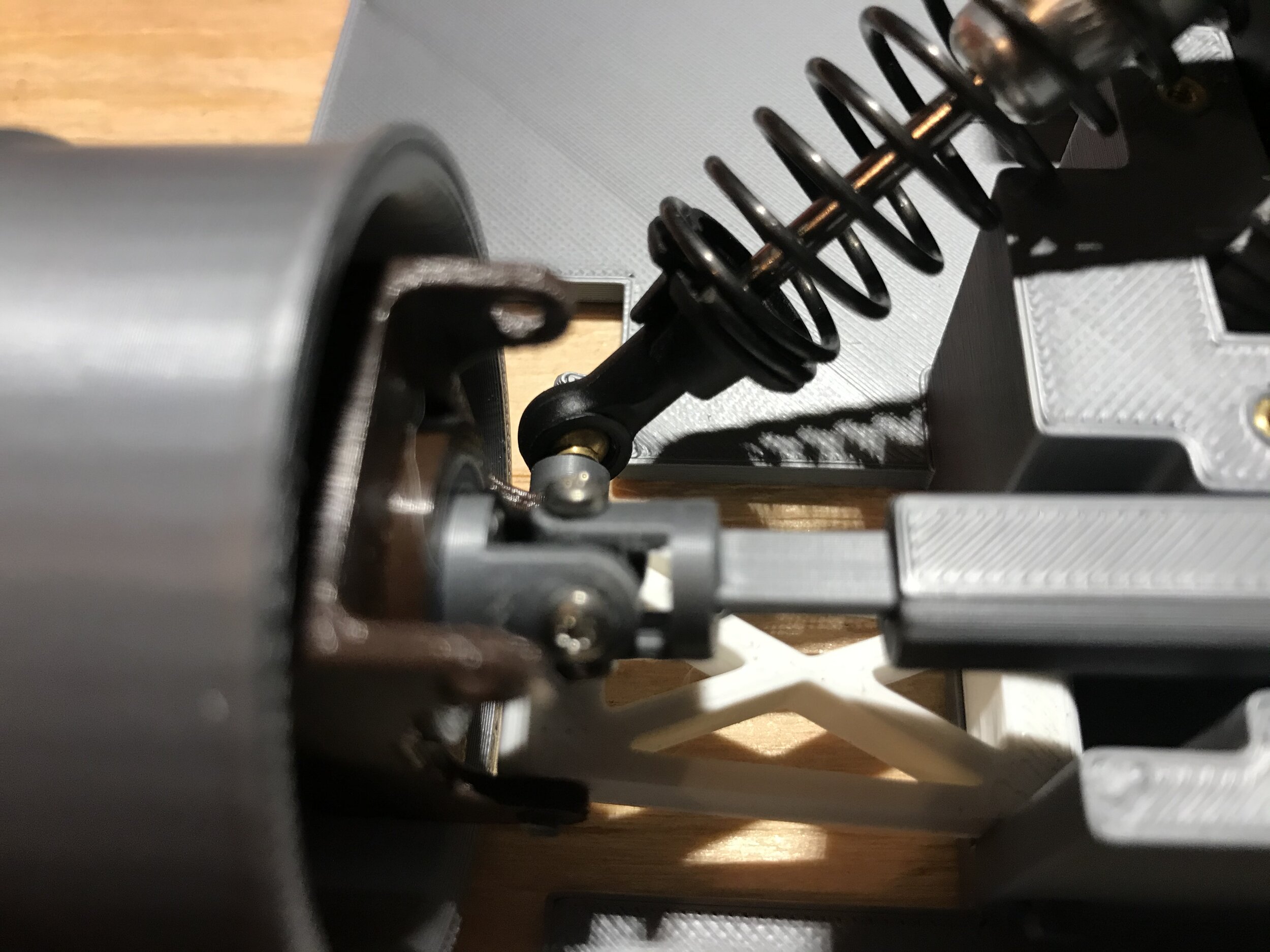

Rear end universal joint and suspension linkage

The PLA universal joint has given me lots of trouble, still evaluating whether or not it’s a feasible challenge.