Lasers at Milwaukee Tool

2020 to 2021

Lasers are used in construction project level, plumb, and straight lines for tradesmen and women to install their systems in a structurally sound, and aesthetically pleasing manner.

We identified an opportunity to make these lasers quicker to set up, and easier to use….

Mechanical Design

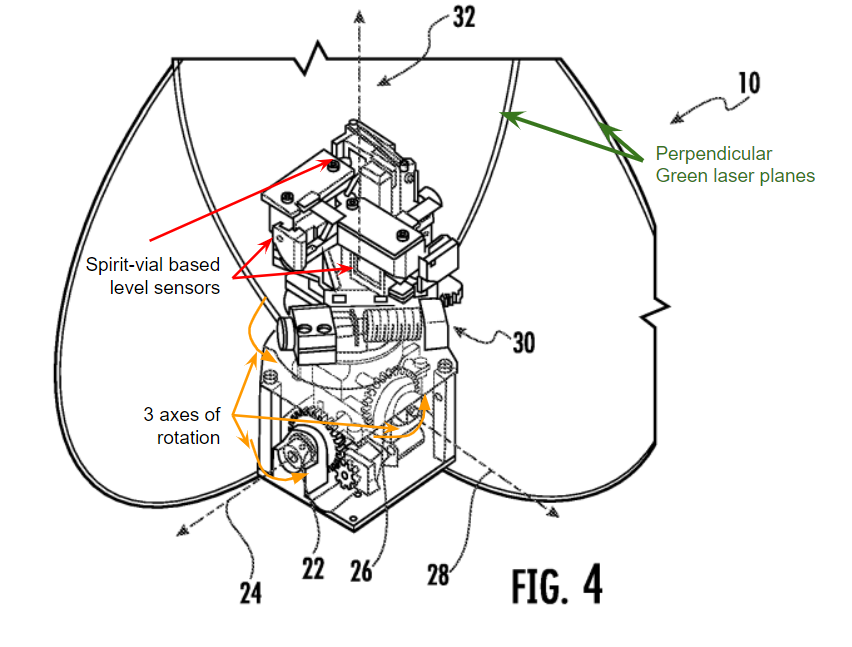

Two-plane motorized leveling laser

This was a motorized laser prototype. Using 3 axes of rotation it could level within a range of +/- 7 degrees.

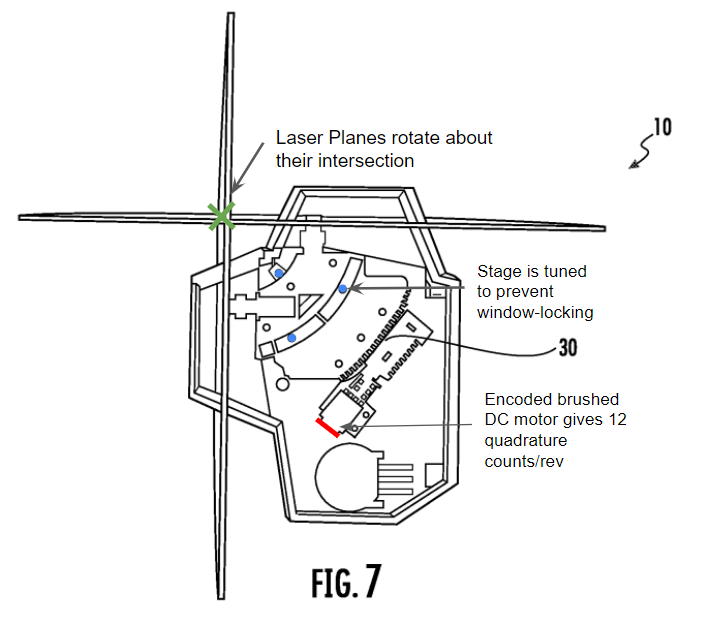

The worm gear and rotating stage are designed to rotate around the intersection of the laser lines. This requirement was driven by user research.

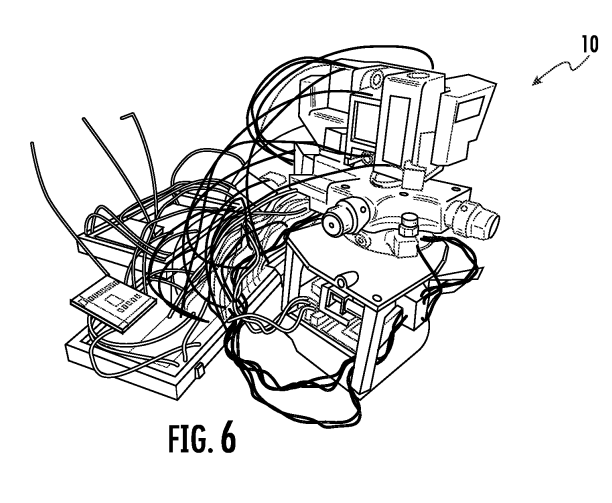

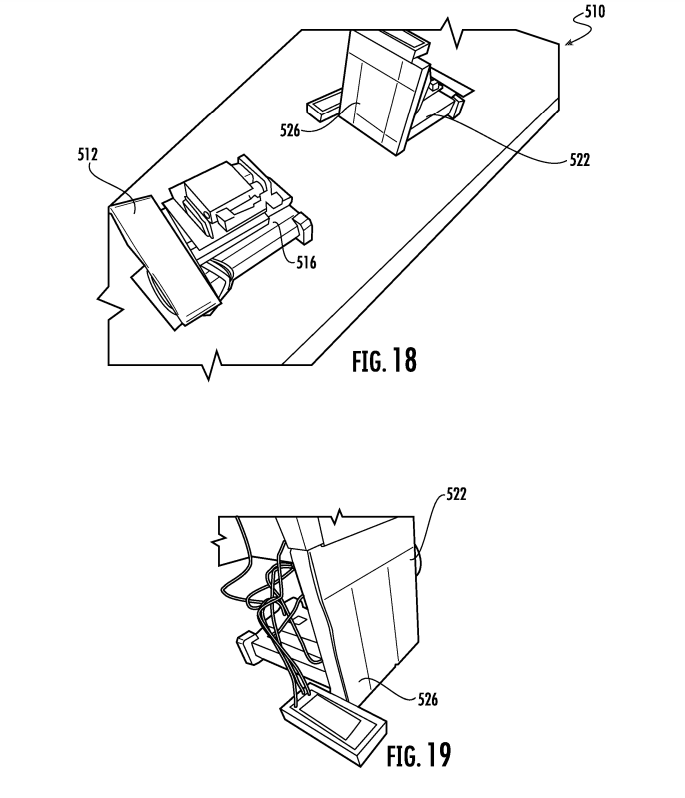

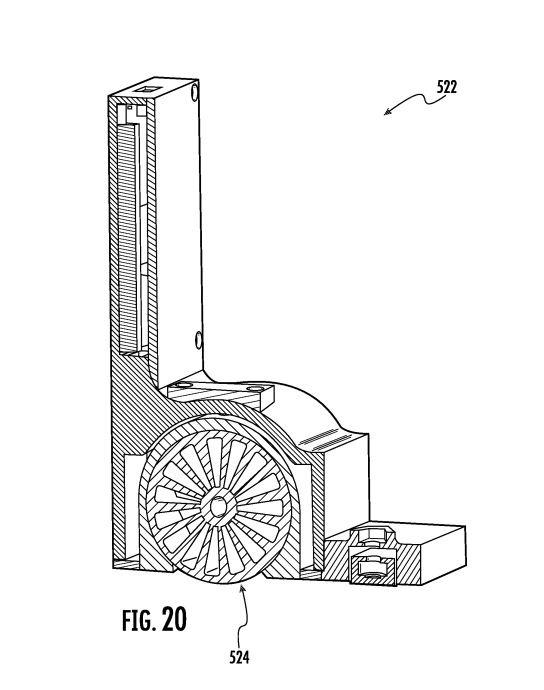

Funny enough, our breadboard prototype for characterizing the vial’s measurement range and dynamic response characteristics made it into the patent…

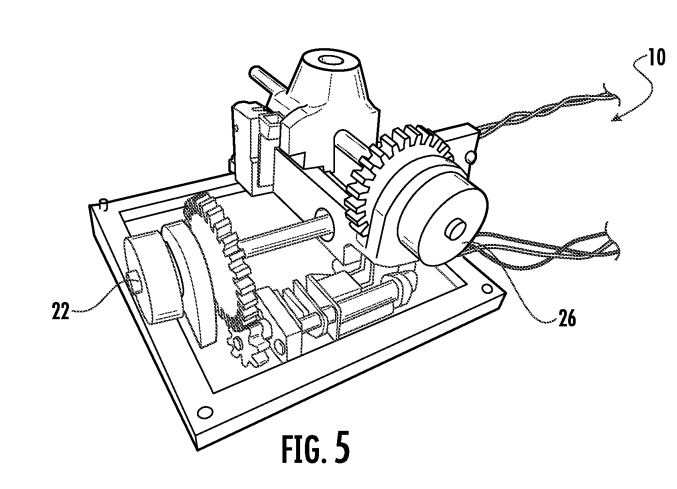

Because of the footprint requirement, we designed our own very compact 2-axis linear stage, which moved a universal joint. Best solution? not by a long-shot, but we’d developed this for a different prototype and so it was a ‘drop-in’ for what we needed.

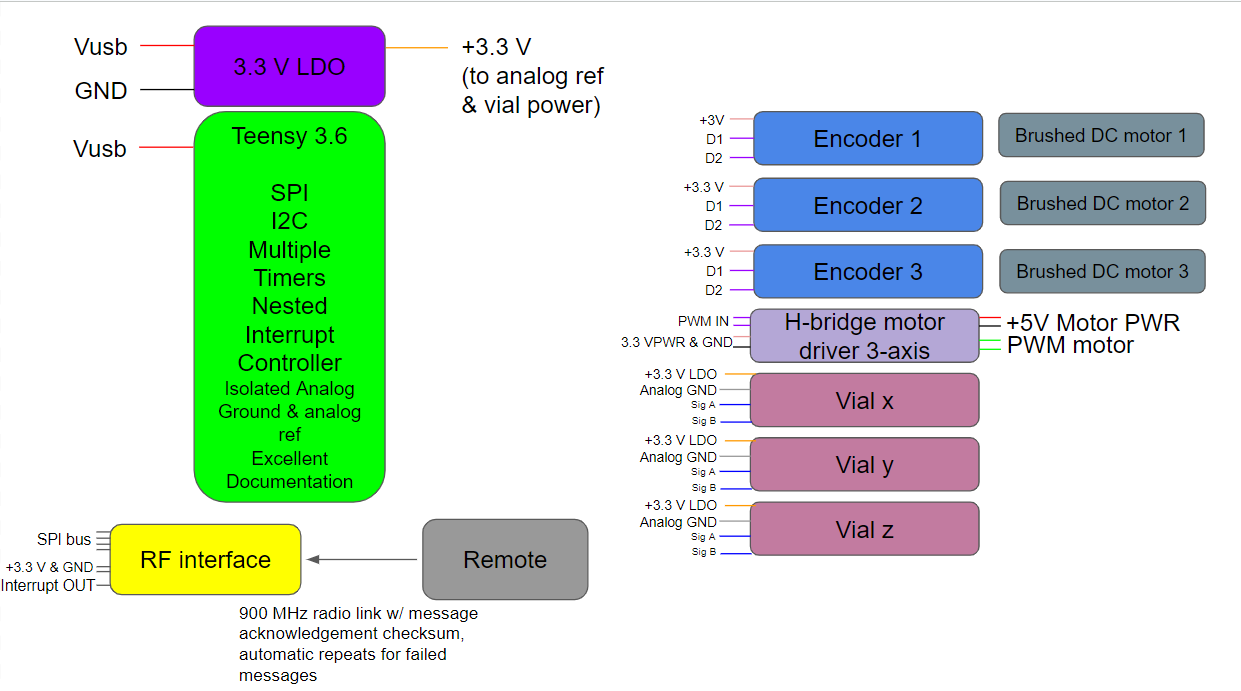

Electrical Integration

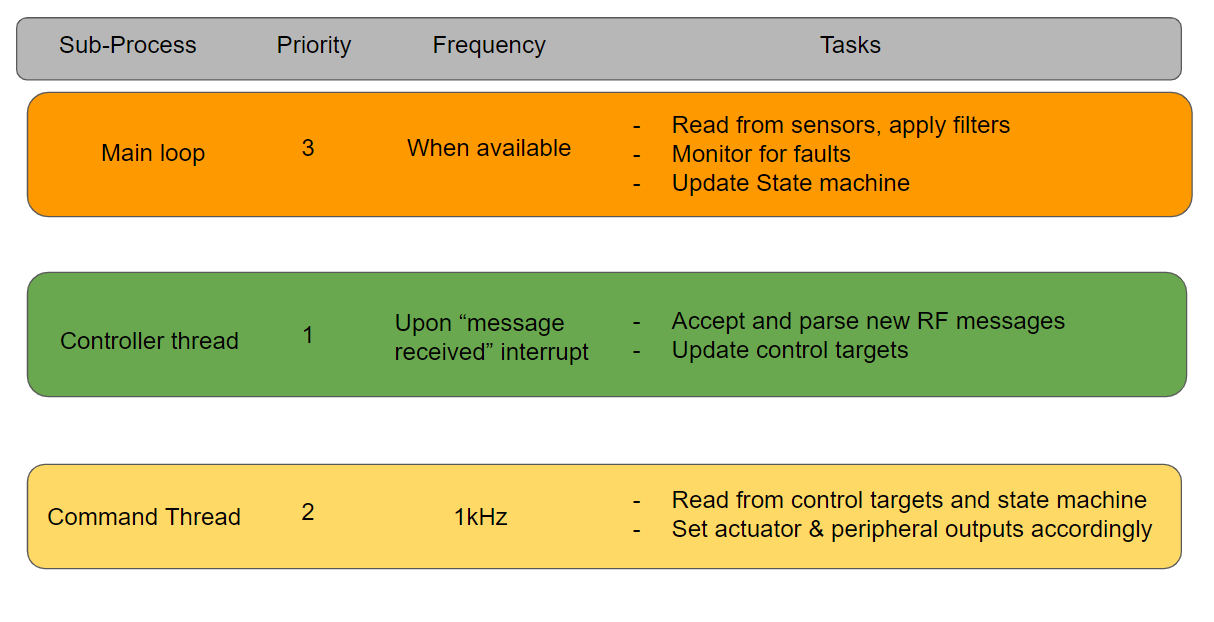

Software Integration

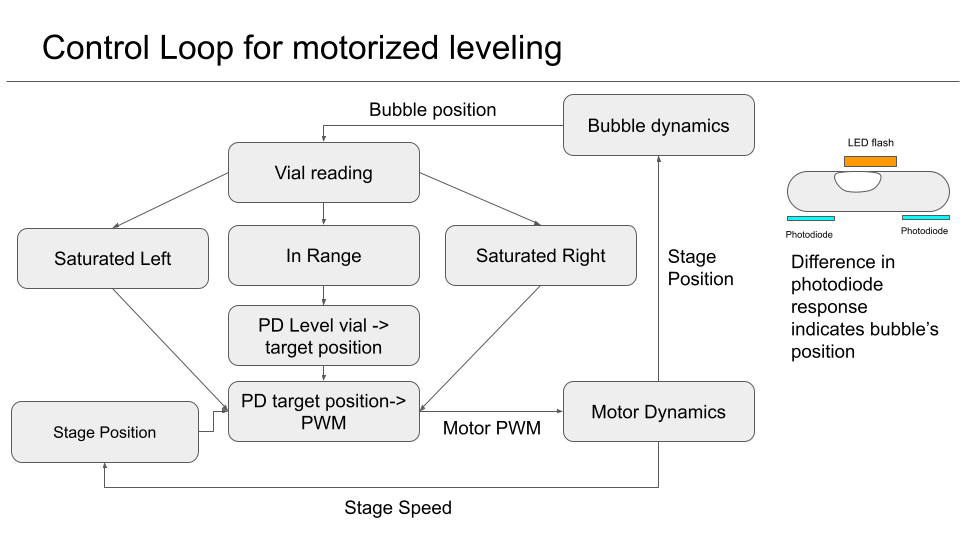

Here’s one of many control diagrams that we used to structure the leveling system’s design from day 1. It dictates mechanical coupling between sensors and actuators, sets the outline for the components included in the electrical schematic and directly translates to the state machine running on the MCU.

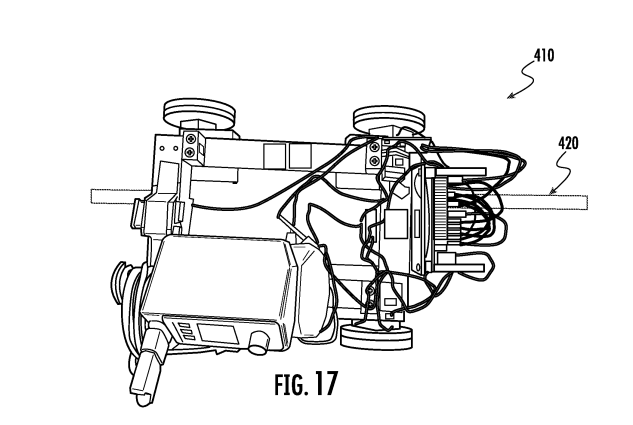

Instrumented Laser rangefinder target

Shown above, an LDM shining at a target, which is instrumented with a wheel and a quadrature encoder. The LDM provided infrequent, relatively accurate, but most importantly drift-free measurements. An encoded wheel provides frequent and high-resolution measurements which are prone to drift.

In classic linear estimation fashion, the wheel can essentially interpolate the LDM’s infrequent measurements. Varying levels of “trust” can be given to the wheel and the LDM, to tune the system to have the desired accuracy, stability, and responsiveness to movement. The operating principle is borrowed from Kalman Filtering, but it would be a stretch to call the filter implemented here “optimal”. For one, we don’t have a good characterization of the uncertainty of each sensor, and for two, optimal accuracy is actually not what we’re going for in this application. Through our user research, we determined that the stability of the displayed measurement is actually the most important factor. It’s good to know when to ignore the right way to do something.

Robo-spot

Lasers AND robots? You tell the robot how far to follow a laser line and BOOM it’s there before you know it. As unpolished as this prototype looked we were able to clearly demonstrate the concept to our users.